Miniature bearings are essential components found in numerous industries, renowned for their ability to handle high rotational speeds and maintain precision in tight spaces. This guide offers an extensive exploration of miniature bearings, covering their diverse types, applications across industries, advantages, and critical selection considerations.

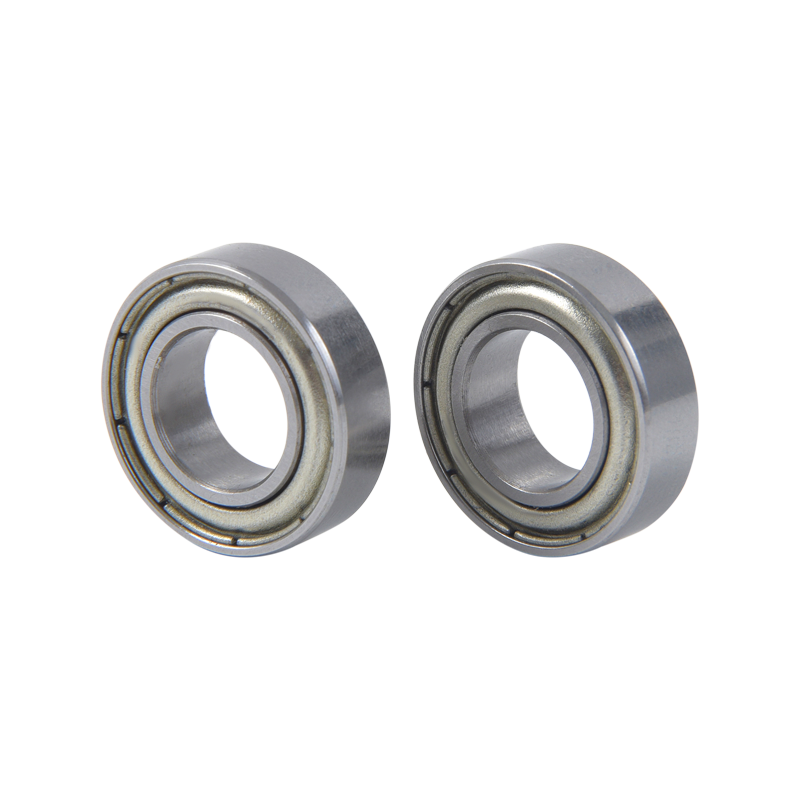

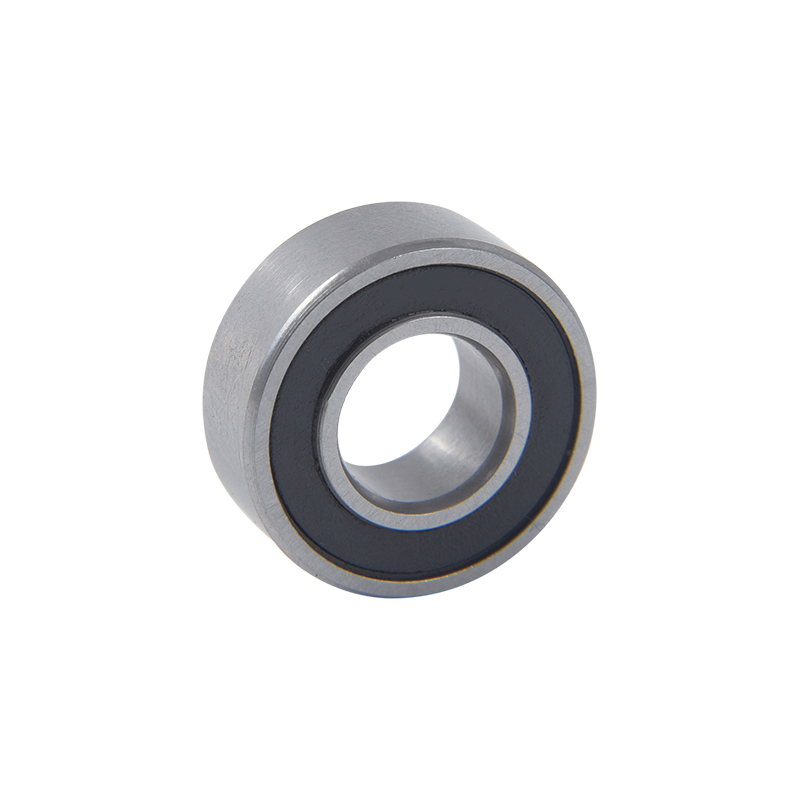

Miniature bearings come in various types, each tailored to specific needs. The most prevalent type is the deep groove ball bearing, well-suited for both radial and axial loads, with options for different materials, designs, and cages. Angular contact ball bearings are designed to handle combined radial and axial loads, ensuring high-speed and precise operations. Thrust bearings are specialized for managing axial loads, commonly used in equipment with rotational movement. Needle roller bearings utilize slender cylindrical rollers, providing high radial load capacity within limited space. Miniature tapered roller bearings combine radial and axial load handling through their tapered design, commonly applied in automotive and industrial settings. Miniature spherical roller bearings utilize a spherical outer ring to manage both radial and axial loads effectively, often used in applications with misalignment or oscillating requirements.

Miniature bearings find diverse applications across industries, showcasing their versatility and importance. In the automotive sector, they are integral components of air conditioning systems, gearboxes, alternators, and various automotive parts requiring efficient rotational mechanisms. The aerospace industry heavily relies on miniature bearings for actuators, navigation systems, gear mechanisms, and other critical components demanding high precision and reliability. In robotics, these bearings are crucial for achieving a compact design and precise movement, making them indispensable in robotic arms, joints, and gearboxes. Additionally, miniature bearings find applications in electric motors, power tools, medical devices, and electronics, contributing to their efficient functionality.

The benefits of miniature bearings are significant and contribute to their widespread usage. They excel in space efficiency due to their compact size, making them suitable for constrained spaces where standard bearings may not fit. Additionally, miniature bearings offer precise performance, crucial for applications that demand high levels of accuracy. They effectively reduce friction during operation, leading to improved efficiency, extended component life, and reduced energy consumption. Miniature bearings are capable of withstanding high rotational speeds, making them ideal for applications that require swift and precise movement. Crafted from premium materials, these bearings offer durability and reliable performance, even under challenging operating conditions.

When selecting miniature bearings, several critical considerations come into play. Understanding the types and magnitude of loads the bearing will endure is vital for choosing the appropriate bearing type and size. Additionally, considering the rotational speed requirements is crucial in selecting a bearing that can effectively operate under the specified speeds. Compatibility and ease of mounting with the existing system should also be taken into account. Proper lubrication methods and materials should be chosen to ensure smooth operation and enhance the bearing's longevity. Accounting for the operating temperature and prevailing environmental conditions is essential to choose bearings that can withstand and perform optimally under these circumstances. Lastly, balancing performance requirements with budget constraints is crucial, ensuring a cost-effective solution without compromising on quality and functionality.

In conclusion, miniature bearings are pivotal components in various industries, providing efficient, precise, and reliable rotational movement within confined spaces. A thorough understanding of their types, applications, benefits, and key considerations is crucial for selecting the most suitable miniature bearing for a specific application, ensuring optimal performance and longevity.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856