Innovations in High-Speed Bearing Materials and Manufacturing Techniques

High-speed bearings play a crucial role in many industrial applications, such as aircraft engines, gas turbines, and high-performance automobiles. Innovations in bearing materials and manufacturing techniques have significantly improved the performance and durability of high-speed bearings. Here are some notable advancements in this field:

Ceramic materials: Ceramic materials such as silicon nitride and zirconia are now commonly used for high-speed bearings due to their excellent strength, hardness, and wear resistance. These materials also have low friction and high-temperature resistance, making them ideal for use in high-speed and high-temperature applications.

Hybrid bearings: Hybrid bearings combine ceramic rolling elements with steel races to provide high-speed capabilities with increased durability and reliability. The ceramic rolling elements reduce friction and wear, while the steel races provide strength and toughness.

Advanced coatings: Various types of coatings, such as diamond-like carbon (DLC) and titanium nitride (TiN), are applied to bearing components to improve their wear resistance and reduce friction. These coatings can also enhance the lubrication properties of the bearing, leading to improved performance and durability.

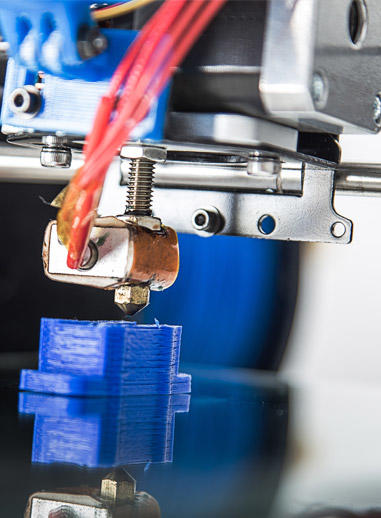

Advanced manufacturing techniques: Advanced manufacturing techniques, such as precision grinding and polishing, laser machining, and electro-discharge machining (EDM), have greatly improved the precision and accuracy of bearing components. These techniques enable the production of complex shapes and designs with tight tolerances, resulting in high-quality bearings with improved performance and durability.

Lubrication innovations: Lubrication is critical to the performance and longevity of high-speed bearings. Innovative lubrication techniques, such as magnetic and hydrodynamic lubrication, have been developed to improve the efficiency and reliability of bearings under high-speed and high-temperature conditions.

Overall, innovations in high-speed bearing materials and manufacturing techniques have significantly improved the performance and durability of high-speed bearings, making them more reliable and efficient for use in a wide range of industrial applications.

Understanding the Physics of High-Speed Bearings

High-speed bearings are an essential component of many industrial and technological applications, such as aerospace, automotive, and manufacturing. These bearings operate at high speeds and often under extreme conditions, requiring a deep understanding of the physics involved in their operation.

The key physics principles governing high-speed bearings are:

Friction: Friction between the bearing surfaces generates heat, which can lead to damage or failure of the bearing. To minimize friction, high-speed bearings typically use materials with low coefficients of friction, such as ceramics or certain metals.

Lubrication: Lubrication is critical to reducing friction and protecting the bearing from wear and damage. High-speed bearings use specialized lubricants that can withstand high temperatures and pressures.

Vibration and Noise: At high speeds, bearings can generate significant vibrations and noise. Engineers must design bearings to minimize these effects to ensure smooth and quiet operation.

Material Properties: The properties of the bearing material can significantly impact its performance. For example, high-speed bearings may use materials that are lightweight, durable, and heat-resistant to improve their performance.

Centrifugal Force: At high speeds, the centrifugal force generated by the rotating bearing can deform or damage the bearing, particularly in applications where the bearing experiences high radial loads. Engineers must design bearings to withstand these forces.

Bearing Geometry: The geometry of the bearing, including the size, shape, and surface finish, can impact its performance at high speeds. Engineers must optimize these factors to ensure the bearing operates at peak efficiency.

Overall, the physics of high-speed bearings is a complex and multi-disciplinary field that requires a deep understanding of mechanics, materials science, and lubrication. By understanding these principles, engineers can design and optimize high-speed bearings for a wide range of industrial and technological applications.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856