The Benefits of 1600 Series Deep Groove Ball Bearings for Industrial Applications

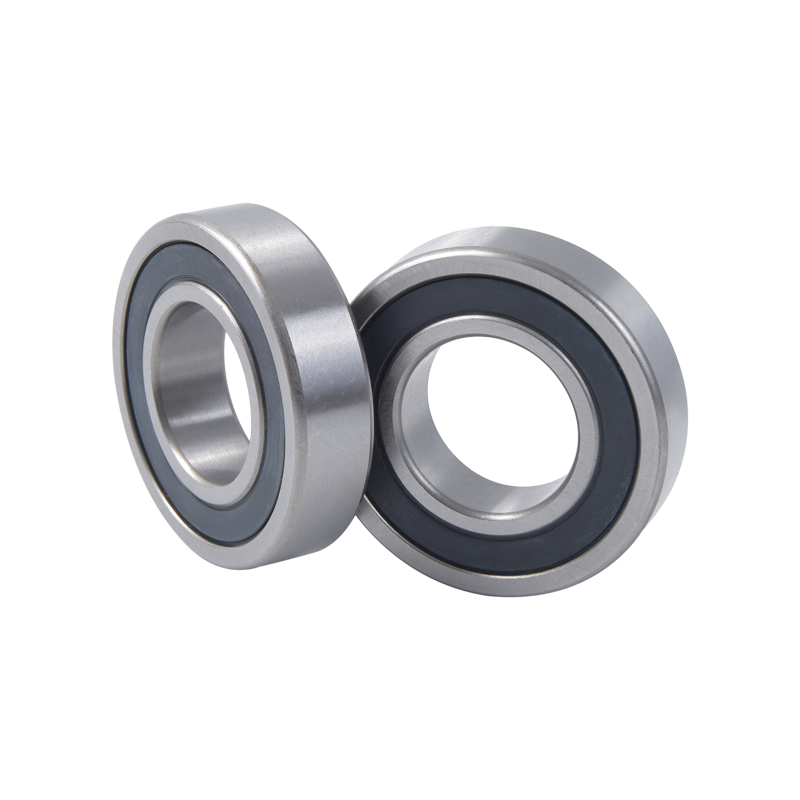

Deep groove ball bearings are widely used in industrial applications for their versatility and ability to handle radial and axial loads. The 1600 series deep groove ball bearings, in particular, offer several benefits that make them an excellent choice for various industrial applications.

High Load Carrying Capacity:The 1600 series deep groove ball bearings have a higher load capacity than standard ball bearings due to their increased ball diameter and number of balls. This makes them suitable for heavy-duty applications where high radial and axial loads are present.

Low Friction:The 1600 series deep groove ball bearings have a low friction coefficient, which results in less heat generation and lower energy consumption. This makes them ideal for applications that require high efficiency and low power consumption.

High Speed:The 1600 series deep groove ball bearings are designed to operate at high speeds, making them suitable for applications that require fast rotational speeds.

Corrosion Resistance:The 1600 series deep groove ball bearings are available in various materials such as stainless steel, which provides excellent corrosion resistance. This makes them ideal for applications in harsh environments such as the food and beverage industry.

Low Noise and Vibration:The 1600 series deep groove ball bearings are designed to minimize noise and vibration levels, making them suitable for applications that require quiet operation, such as in the medical and dental industry.

Easy to Install: The 1600 series deep groove ball bearings are easy to install and require little maintenance. They come in various sizes and designs, making them suitable for different applications.

Conclusion:The 1600 series deep groove ball bearings offer several benefits that make them an excellent choice for various industrial applications. Their high load capacity, low friction, high speed, corrosion resistance, and low noise and vibration levels make them a versatile and reliable option for many industries.

Exploring the Design and Features of 1600 Series Deep Groove Ball Bearings

Deep groove ball bearings are an essential component of various mechanical systems, including automotive, aerospace, industrial, and medical equipment. The 1600 series deep groove ball bearings are a popular choice among engineers due to their excellent load carrying capacity, low friction, and high durability. Let's explore the design and features of the 1600 series deep groove ball bearings in more detail.

The 1600 series deep groove ball bearings have a simple design that consists of an inner ring, an outer ring, a cage, and balls. The inner and outer rings are made of high-quality steel, while the cage is typically made of brass or synthetic materials. The balls are usually made of chrome steel or ceramic.

In summary, the 1600 series deep groove ball bearings have a simple design but offer excellent load carrying capacity, low friction, and high durability. These features, coupled with their ease of installation and versatility, make them a popular choice for various mechanical systems.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856