Non-Standard Bearings: Innovative Solutions for Unique Challenges

Non-standard bearings refer to any type of bearing that does not fit the typical design and specifications of standard bearings. These bearings are often used to solve unique challenges in various industries, such as aerospace, automotive, and medical.

Non-standard bearings come in a wide range of shapes, sizes, and materials to meet specific application requirements. Here are some examples of innovative solutions that non-standard bearings can offer:

Customized shapes: Non-standard bearings can be designed in customized shapes to fit into unique spaces or accommodate complex load requirements. For example, a bearing may need to be thin and long to fit into a small space, or have an irregular shape to support a component with an unusual geometry.

Special materials: Non-standard bearings can be made from a variety of materials beyond the typical steel or ceramic. For example, a bearing may need to be made from a lightweight material such as aluminum or titanium for aerospace applications, or from a non-metallic material such as plastic for medical applications.

Extreme temperature resistance: Non-standard bearings can be designed to withstand extreme temperatures, such as those found in high-temperature industrial applications or in cryogenic environments. Special materials and lubricants can be used to ensure that the bearings function properly in these conditions.

Corrosion resistance: Non-standard bearings can be designed to resist corrosion, such as in marine or chemical processing applications. Bearings can be coated with materials such as chrome, nickel, or zinc to protect them from corrosion.

High-speed capabilities: Non-standard bearings can be designed to operate at high speeds, such as in turbine or motor applications. These bearings may require special materials, lubricants, and precision manufacturing processes to ensure that they can handle the high speeds without damage.

Overall, non-standard bearings offer a wide range of innovative solutions to unique challenges in various industries. By working with a bearing manufacturer that specializes in non-standard bearings, companies can find the best solution to meet their specific application requirements.

Designing Non-Standard Bearings for Maximum Performance and Efficiency

Designing non-standard bearings for maximum performance and efficiency requires a thorough understanding of the specific application requirements and a focus on key design considerations. Here are some factors to consider when designing non-standard bearings:

Load capacity: The load capacity of a bearing is a critical factor in determining its performance and efficiency. The bearing must be designed to handle the maximum load requirements of the application while maintaining proper clearance and minimizing friction.

Environmental factors: The environmental factors of the application will also need to be considered when designing the bearing. Factors such as temperature, humidity, and exposure to chemicals or contaminants can impact the bearing's performance and longevity.

Material selection: The material selection for the bearing is critical to ensure maximum performance and efficiency. Materials with high strength-to-weight ratios, low coefficients of friction, and high-temperature resistance will provide the best performance and longevity.

Lubrication: The lubrication of the bearing is crucial to reduce friction and wear. The lubricant should be selected based on the operating speed and temperature range of the application.

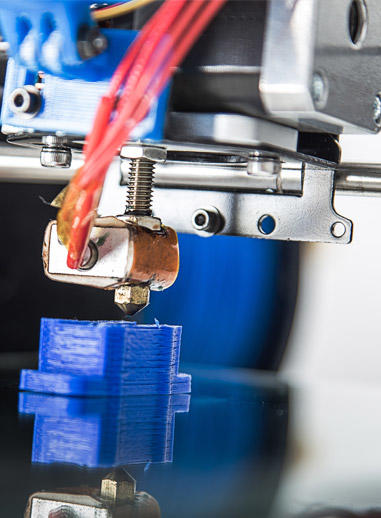

Manufacturing process: The manufacturing process used to produce the non-standard bearing must be carefully considered to ensure that the bearing meets the required specifications. Precision manufacturing processes such as CNC machining, grinding, and honing may be required to achieve the necessary tolerances and surface finishes.

Overall, designing non-standard bearings for maximum performance and efficiency requires a focus on the specific application requirements and careful consideration of key design factors. By working with a bearing manufacturer that specializes in non-standard bearings, companies can ensure that their bearings are designed to meet their unique needs and provide optimal performance and efficiency.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856