Amidst the intricate symphony of machinery and engineering, an inconspicuous yet profoundly vital performer takes center stage: the miniature bearing. These diminutive yet mighty components play an indispensable role across a diverse array of mechanical systems, underscoring the timeless adage that significance surpasses mere size.

Miniature bearings operate as the unsung heroes, facilitating seamless movement and exactitude within an impressive range of applications. From electronics and medical devices to the expansive realms of automotive and aerospace technologies, these unassuming champions shoulder the responsibility of reducing friction, enabling smooth rotation, and orchestrating the harmonious interaction of moving parts. Ultimately, they contribute to the overall efficiency and lasting functionality of intricate machinery.

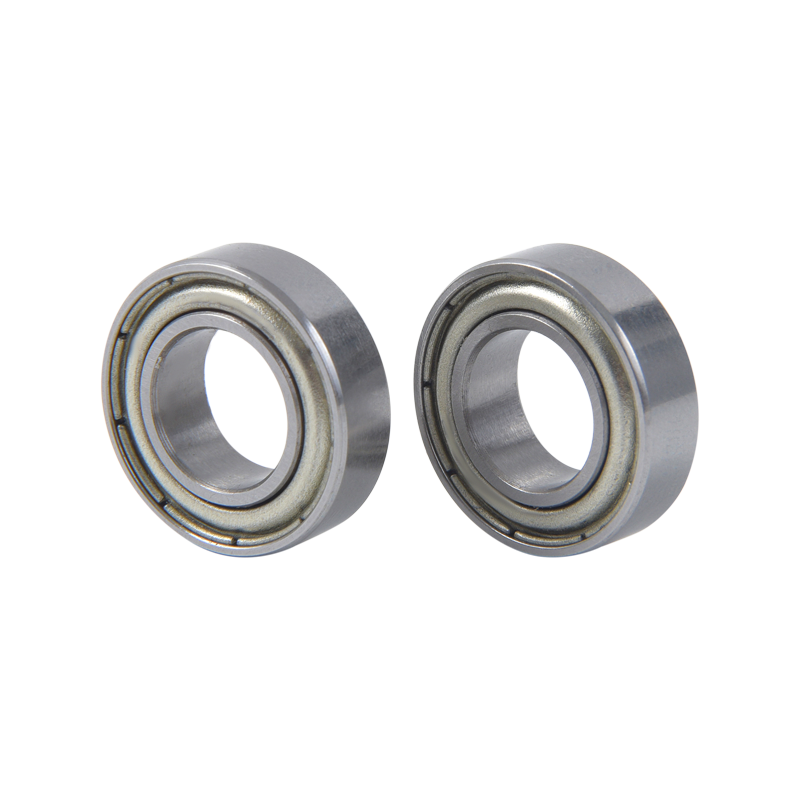

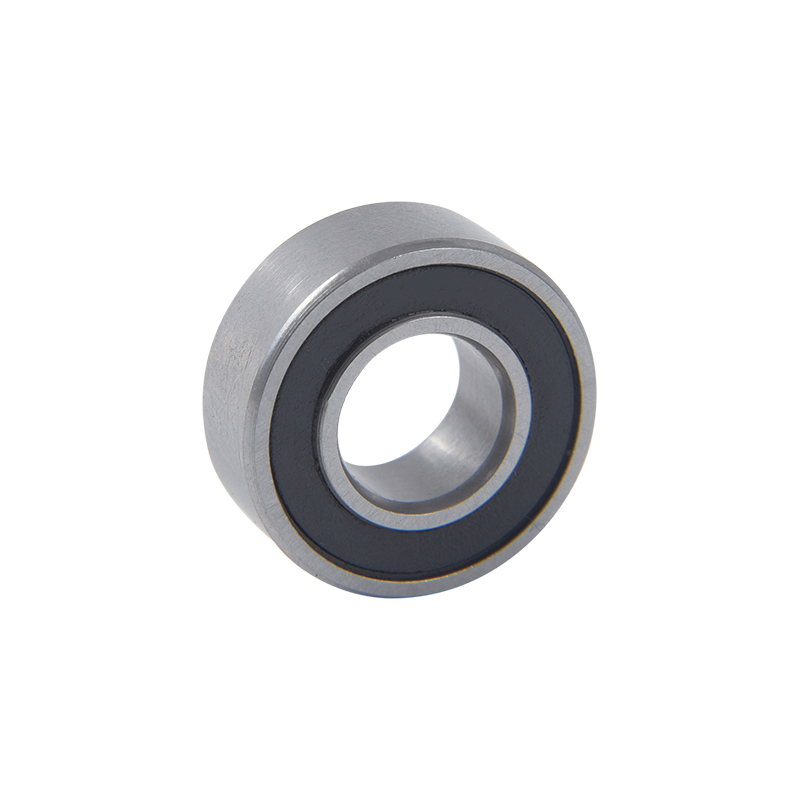

At the heart of miniature bearings lies the precision of engineering—a craft that takes center stage in their creation. Crafted to meticulous standards, these bearings embody precise tolerances and minimal clearances, endowing them with the remarkable ability to excel even under the rigors of demanding conditions. They exhibit an impressive capacity to withstand high speeds, accommodate varying loads, and adeptly navigate oscillating movements, all while maintaining unwavering structural integrity.

Yet, the significance of miniature bearings extends far beyond their mechanical prowess. Their compact design holds the key to optimizing space—a vital consideration in modern engineering landscapes where efficiency and compactness are paramount. This inherent smallness proves invaluable, particularly in applications where spatial limitations dictate the dimensions of components. Here, miniature bearings step in as indispensable allies, ensuring optimal performance within confined environments.

However, the impact of miniature bearings transcends the realm of mechanics, delving deep into the domain of material science. Forged from an impressive array of high-performance materials, including stalwarts like stainless steel, ceramics, and synthetic polymers, these bearings boast exceptional durability and a natural resistance to corrosion. This resilience becomes particularly critical in applications where exposure to demanding environmental factors, aggressive chemicals, or extreme temperature fluctuations prevails.

In the grand narrative of innovation, miniature bearings assume the role of catalysts, propelling progress across a myriad of domains. They spearhead the evolution of miniaturized electronic devices, refine the precision of medical instruments, and contribute to the intricacy of mechanisms that drive various fields forward. The smooth, frictionless movement facilitated by miniature bearings serves as the foundational cornerstone upon which engineers erect new tiers of performance and functionality, driving an unceasing quest for advancement.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856