High-speed bearings represent an engineering feat that has revolutionized precision and speed across numerous industries. These specialized bearings are vital components in applications where rapid rotational speeds, minimal friction, and exceptional precision are essential. This article delves into the world of high-speed bearings, exploring how they have reshaped technology and various sectors.

High-speed bearings play a pivotal role in aerospace engineering. In aircraft engines, they enable turbine blades to spin at astonishing speeds while maintaining low friction and minimal heat generation. This translates to enhanced fuel efficiency, reduced maintenance requirements, and improved overall performance.

The automotive industry has also witnessed a transformation due to high-speed bearings. These bearings are integral to engines, transmissions, and wheel hubs, ensuring smoother and more efficient power transfer. The result is improved fuel economy, heightened vehicle performance, and a quieter, more comfortable driving experience.

Precision manufacturing relies heavily on high-speed bearings to meet the exacting standards of modern industry. Machine tools such as lathes, mills, and grinders depend on these bearings to achieve high levels of accuracy and consistency in the production of intricate components, enhancing overall efficiency and reliability.

In the medical field, high-speed bearings are critical for precise, vibration-free operation in devices such as dental drills, surgical instruments, and advanced MRI machines. This enhances patient comfort and the effectiveness of medical procedures.

High-speed bearings also play a vital role in the development and operation of high-speed trains. Bearings in train wheels and axles ensure smooth, high-velocity travel while reducing wear and tear on tracks and components, contributing to safer and more efficient rail transport systems.

Wind turbines, essential for renewable energy generation, rely on high-speed bearings to enable seamless rotation of turbine blades. This ensures maximum energy output even in varying wind conditions, underpinning the efficiency and viability of wind energy.

In the electronics and data storage realm, high-speed bearings are indispensable components in the spindle motors of hard disk drives. They facilitate rapid data access and unwavering reliability, critical for modern computing.

In robotics, where precision and speed are paramount, high-speed bearings are extensively used in joints and actuators. This empowers robots to perform tasks with remarkable accuracy and agility, impacting manufacturing, automation, medical applications, and space exploration.

These remarkable achievements in high-speed bearing technology are the result of key innovations:

Advanced Materials: The use of cutting-edge materials such as ceramics and high-performance alloys has significantly improved bearing durability and reduced friction, pushing the boundaries of what is achievable.

Lubrication Mastery: Engineers have developed specialized lubrication techniques, including solid lubricants and high-temperature greases, ensuring seamless bearing operation even under extreme conditions.

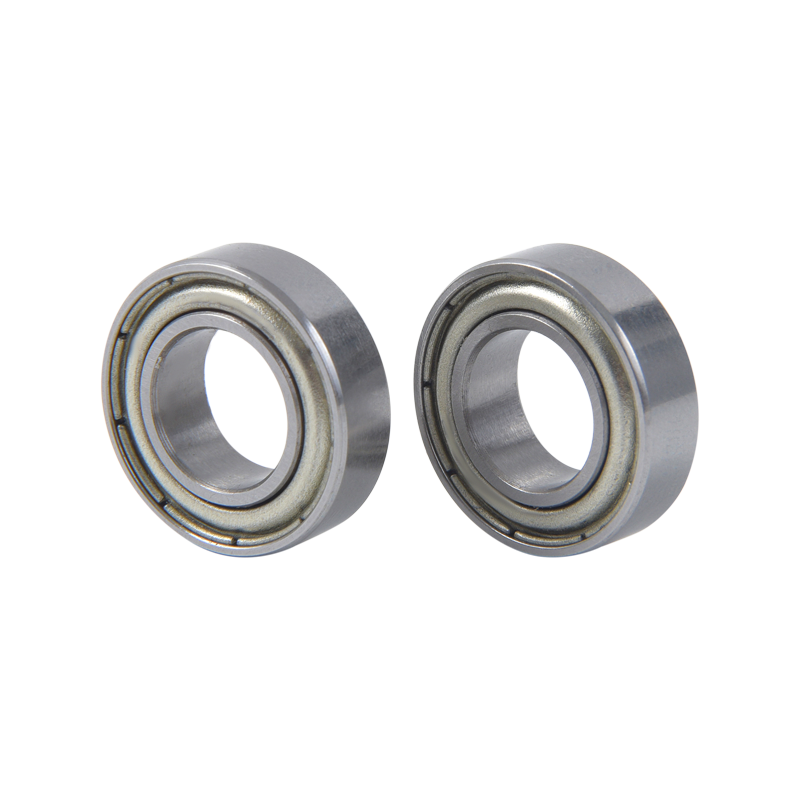

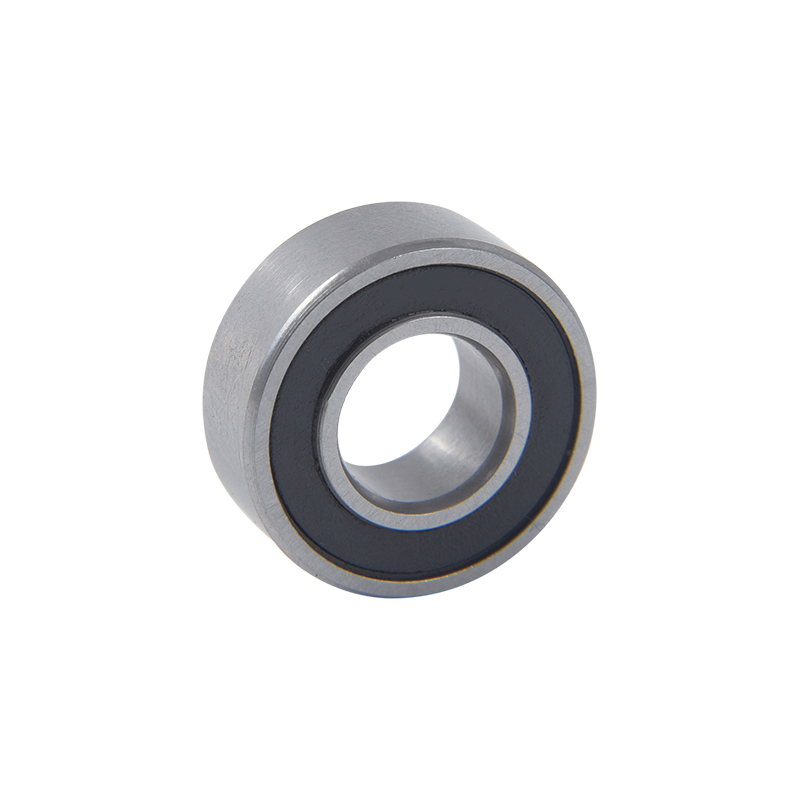

Design Excellence: Continuous design optimization has yielded bearings with enhanced geometries, cage materials, and sealing mechanisms, elevating their performance to unprecedented levels of efficiency and reliability.

Precision Manufacturing: Precision manufacturing processes such as CNC machining and superfinishing have enabled the creation of bearings with exceptionally tight tolerances, essential for their outstanding performance.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856