Inch flanged bail bearings play a crucial role in enhancing the efficiency of small power motors through various mechanisms and design features. Below, we delve into the intricacies of how these bearings contribute to the overall efficiency of small power motors.

Reduced Friction and Wear: One of the primary ways inch flanged bail bearings enhance efficiency is by reducing friction and wear within the motor system. These bearings are engineered with precision and often incorporate advanced materials such as hardened steel or self-lubricating polymers. The smooth surface and precise tolerances of the bearing components minimize friction between moving parts, leading to less energy loss due to heat generation and wear over time.

Optimized Load Distribution: Inch flanged bail bearings are designed to distribute radial and axial loads effectively, ensuring that the motor operates under optimal conditions. By evenly distributing the forces exerted on the rotating shaft, these bearings prevent localized stress points that can lead to premature wear and decreased efficiency.

Enhanced Alignment Stability: Proper alignment of motor components is essential for efficient operation. Inch flanged bail bearings provide stability and support to the rotating shaft, helping to maintain alignment even under varying loads and operating conditions. This stability minimizes vibration and misalignment, which can negatively impact efficiency by causing additional friction and energy loss.

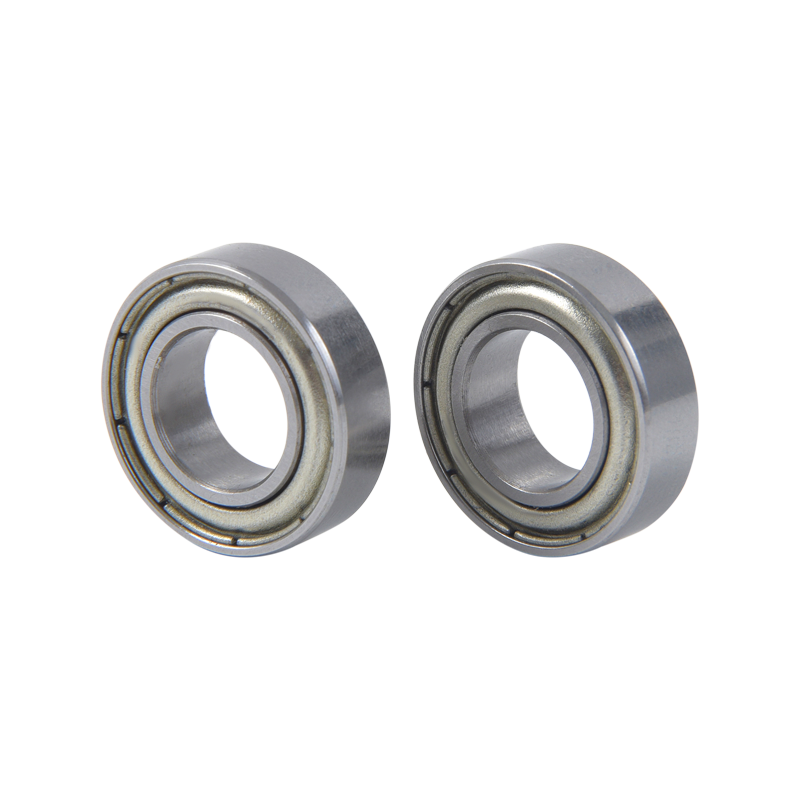

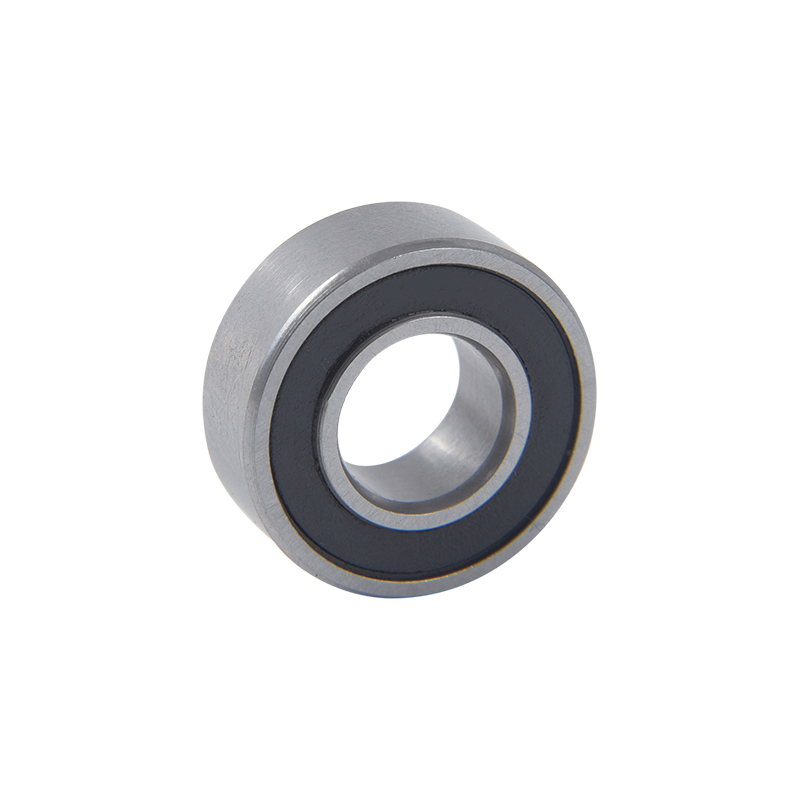

Sealing and Contamination Protection: Many inch flanged bail bearings feature sealing mechanisms or protective coatings to prevent contamination from dust, moisture, and other environmental factors. By keeping contaminants out of the bearing assembly, these features reduce the risk of premature wear and maintain efficient operation over time. Additionally, sealed bearings retain lubrication more effectively, further reducing friction and energy loss.

Temperature Management: Efficient heat dissipation is critical for small power motors to prevent overheating and maintain optimal performance. Inch flanged bail bearings may incorporate heat-resistant materials or special designs to facilitate heat transfer away from critical components. By effectively managing temperatures within the motor system, these bearings help prevent energy loss due to thermal inefficiencies and contribute to overall efficiency.

Compatibility and Customization: Manufacturers often offer inch flanged bail bearings in a range of sizes, configurations, and materials to suit the specific requirements of different small power motor applications. By selecting bearings that are precisely tailored to the motor's design and operating conditions, engineers can maximize efficiency and performance while minimizing unnecessary energy consumption.

Maintenance-Friendly Design: Inch flanged bail bearings are typically designed for ease of maintenance, allowing for quick and convenient replacement when necessary. Proper maintenance, including regular inspection and lubrication, is essential for preserving efficiency and extending the service life of small power motors. The accessibility and serviceability of these bearings contribute to overall efficiency by facilitating proactive maintenance practices.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856