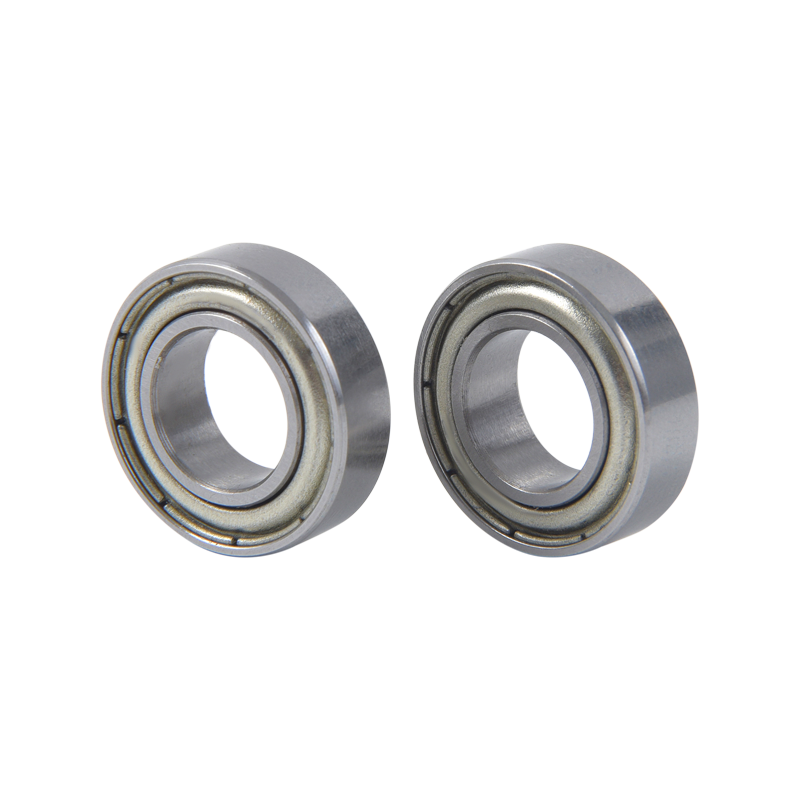

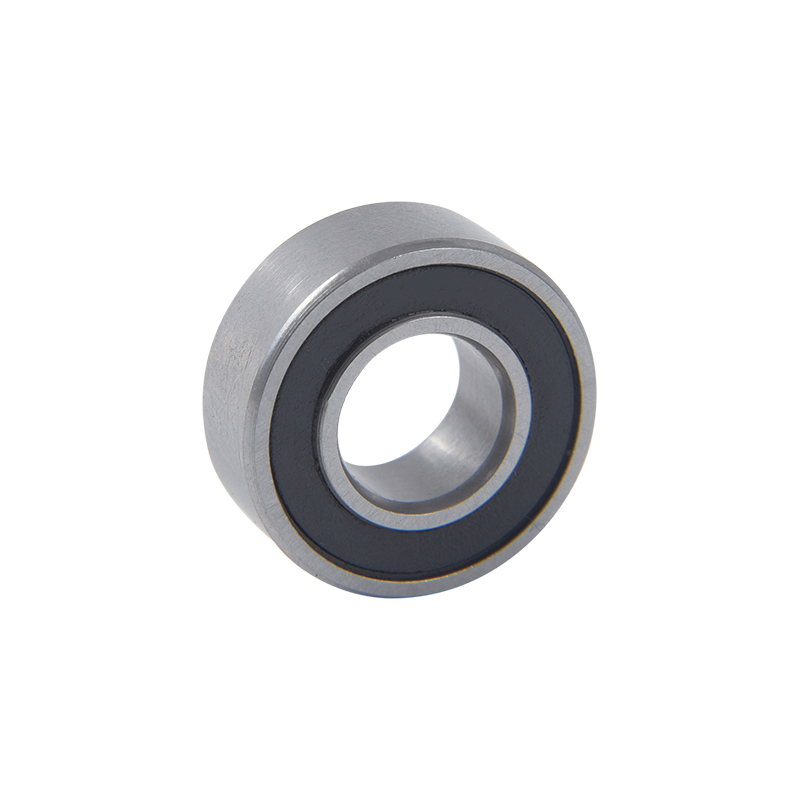

Non-standard bearings, also known as custom or specialized bearings, are tailored to meet unique requirements that standard bearings may not satisfy. These bearings are designed for specific applications and industries where standard bearings might fall short in providing optimal performance. Here's an in-depth exploration of non-standard bearings and their diverse applications in various industries.

In the aerospace industry, non-standard bearings are crucial components, finding applications in aircraft engines, landing gear systems, control systems, and various other critical components. These specialized bearings are designed to be lightweight, highly precise, and exceptionally durable to meet the stringent demands of the aerospace sector.

The automotive industry heavily relies on non-standard bearings for specialized applications such as turbochargers, gearbox systems, steering mechanisms, and suspension systems. These custom bearings are engineered to ensure high performance, efficiency, and reliability within the automotive domain.

In the realm of medical devices and equipment, specialized bearings are a necessity. They provide precise movement and positioning in instruments like medical imaging machines, robotic surgery devices, and prosthetics, meeting the exacting requirements of the healthcare sector.

Robotics and automation applications extensively use non-standard bearings to facilitate smooth and accurate movement in various joints, actuators, and mechanisms. These specialized bearings play a critical role in robotic arms, automation systems, and other machinery, ensuring precision and efficiency in operations.

The oil and gas industry relies on non-standard bearings for harsh and demanding environments, including offshore drilling rigs and subsea equipment. These bearings must endure extreme temperatures, pressures, and corrosive conditions, making them vital components in this sector.

Within the marine industry, specialized bearings are utilized for applications such as ship propulsion systems and navigation equipment. These bearings are designed to withstand high loads, vibrations, and exposure to corrosive saltwater.

Heavy machinery, construction equipment, and mining machinery benefit from non-standard bearings that can endure heavy loads, shocks, and intense operating conditions. These custom bearings ensure the robust performance of these machines under challenging circumstances.

In renewable energy applications like wind turbines and solar tracking systems, non-standard bearings are integral. They are engineered to withstand environmental conditions while providing smooth rotation for optimal efficiency in harnessing renewable energy.

In the food and beverage sector, specialized bearings are essential for applications in food processing and packaging equipment. These bearings meet stringent hygiene and sanitary requirements while delivering reliable performance.

The textile industry benefits from non-standard bearings designed to handle high speeds, loads, and continuous operation. They contribute to the smooth operation of spinning, weaving, and knitting equipment, ensuring seamless production processes.

Custom bearings are meticulously crafted by manufacturers in collaboration with engineers and end-users, considering specific requirements, environmental conditions, and performance expectations. Advanced materials, unique designs, and specialized coatings are employed in the engineering of these bearings to deliver optimal performance and longevity in the diverse industrial landscape.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856