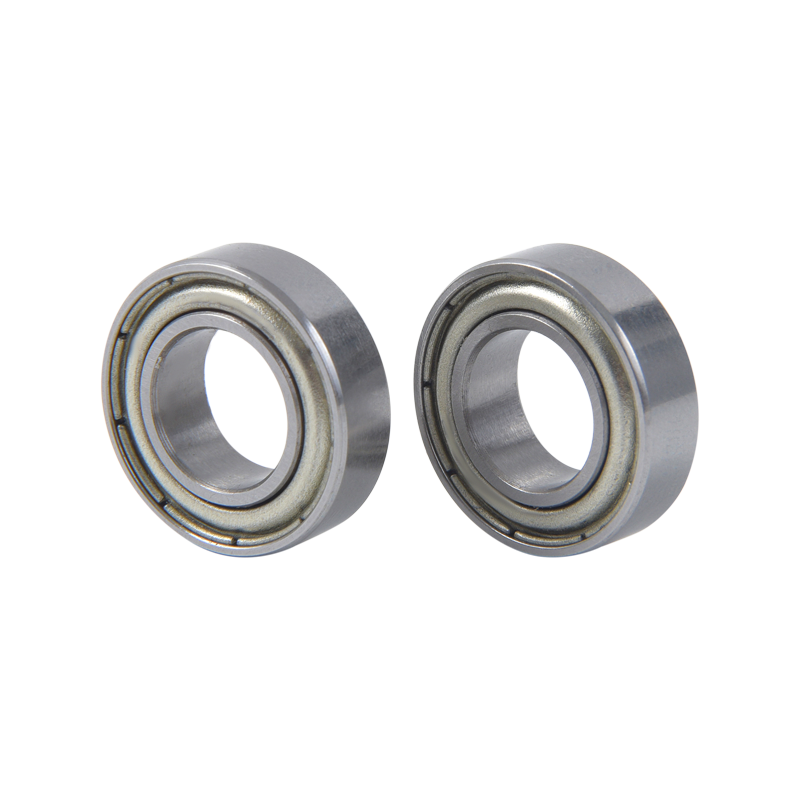

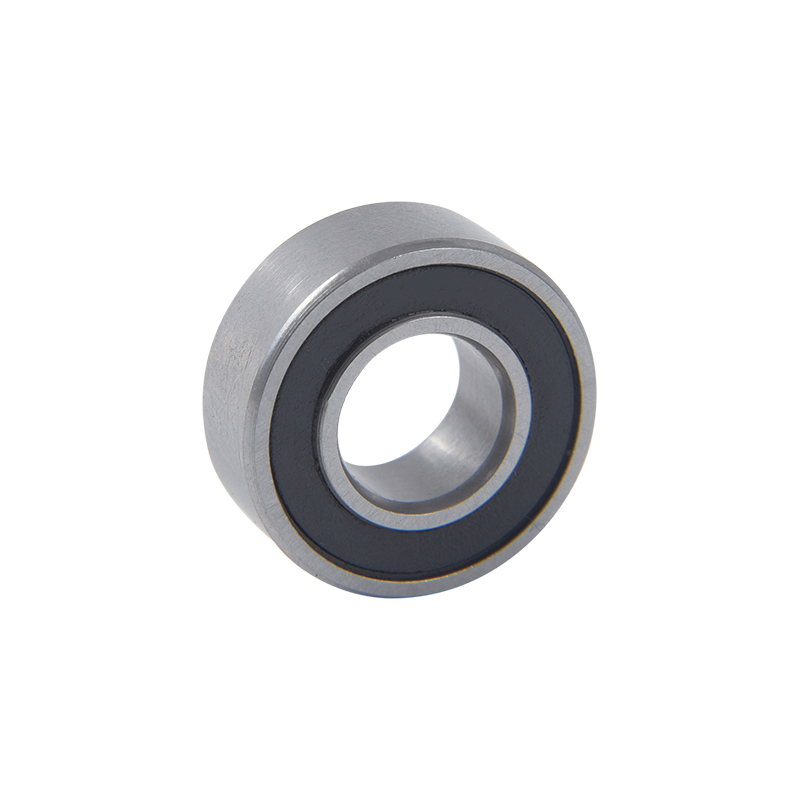

In the dynamic world of machinery, where forces act in multiple dimensions, the finesse with which Deep Groove Ball Bearings (DGBBs) handle axial loads emerges as a testament to engineering excellence. These bearings, designed with meticulous attention to detail, showcase a unique capability to manage axial forces parallel to the axis of rotation.

Axial loads, or forces acting parallel to the axis of rotation, pose a distinctive challenge to machinery. In scenarios where thrust forces come into play, the ability of Deep Groove Ball Bearings to handle axial loads with finesse becomes crucial. The intricate design of these bearings ensures that axial forces are not only managed but distributed evenly, preventing undesirable effects such as vibration and wear.

At the heart of axial load handling is the precision in the design of Deep Groove Ball Bearings. The arrangement of balls within the bearing, along with the quality of materials used, allows for efficient transmission and distribution of axial forces. This precision prevents concentrated stress points, ensuring that the bearing can withstand axial loads without compromising its structural integrity.

One of the hallmarks of axial load handling in DGBBs is the ability to maintain equilibrium. As axial forces come into play, the bearings distribute these forces evenly across the raceways and balls. This balanced approach not only minimizes the risk of localized wear but also ensures that rotational motion remains stable and free from the jarring effects of uneven force distribution.

The finesse with which Deep Groove Ball Bearings handle axial loads translates directly into the stability of rotational motion. In applications where axial forces are prevalent, such as in gearboxes or thrust-bearing scenarios, the bearings act as stabilizers. The precision with which they manage axial loads contributes to smooth, vibration-free operation, enhancing the overall efficiency and performance of the machinery.

The ability to handle axial loads with finesse renders Deep Groove Ball Bearings versatile across a spectrum of applications. From automotive systems dealing with varying road conditions to industrial machinery subjected to thrust forces, these bearings prove their mettle. The versatility in axial load handling allows engineers to rely on DGBBs in diverse settings, confident in their capacity to maintain stability and operational integrity.

Beyond immediate performance, the finesse with which DGBBs handle axial loads has implications for the longevity of the bearings and the machinery as a whole. By preventing uneven wear and reducing the risk of structural damage under axial forces, these bearings contribute to extended operational life.

Engineers tasked with selecting bearings for applications with axial loads must consider various factors. The precision of the bearing's design, the quality of materials used, and the anticipated magnitude of axial forces all play crucial roles. Understanding the finesse with which DGBBs handle axial loads allows for informed decisions in designing machinery that demands stability and reliability.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856