Micro precise deep groove ball bearings are engineered with specific design features tailored to meet the demanding requirements of precision applications in various industries. These bearings, characterized by their miniature size and exceptional precision, play a crucial role in devices where tight tolerances and high rotational speeds are essential. Here are the key design features of micro precise deep groove ball bearings:

Miniature Size: Micro precise deep groove ball bearings are designed to be extremely compact, with outer diameters typically ranging from a few millimeters to around 20 millimeters. This compact size allows them to be used in applications where space is limited, such as small electronic devices and miniature machinery.

High Precision: These bearings are manufactured to extremely tight tolerances to ensure precise alignment and smooth operation. The precision of micro precise deep groove ball bearings is crucial in applications where even minor deviations can lead to performance issues or failures.

Deep Groove Geometry: The deep groove geometry of these bearings allows them to accommodate both radial and axial loads. This design feature ensures efficient load distribution across the bearing's surfaces, resulting in enhanced performance and durability.

Smooth Running: Micro precise deep groove ball bearings are engineered for smooth and quiet operation, even at high speeds. They are often equipped with advanced lubrication systems and optimized internal geometries to minimize friction and reduce noise levels.

High-Speed Capability: Due to their precision construction and low friction design, these bearings are capable of operating at extremely high speeds without sacrificing performance or reliability. This makes them ideal for applications requiring rapid rotational motion, such as high-speed spindles and precision instruments.

Material Selection: The materials used in the construction of micro precise deep groove ball bearings are carefully chosen to maximize strength, durability, and corrosion resistance. Common materials include stainless steel, chrome steel, and ceramic, each offering unique benefits depending on the application requirements.

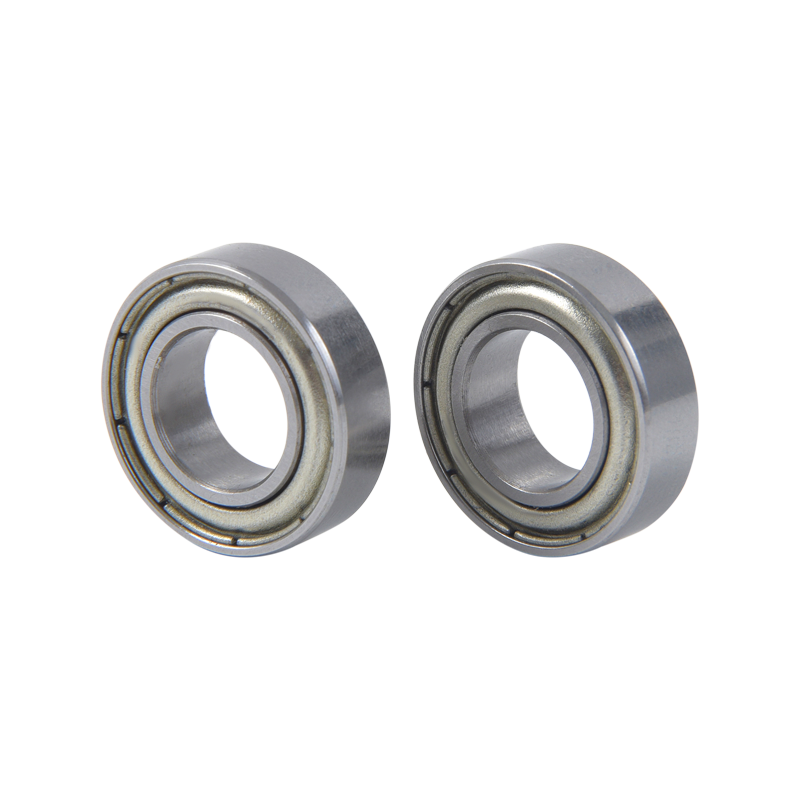

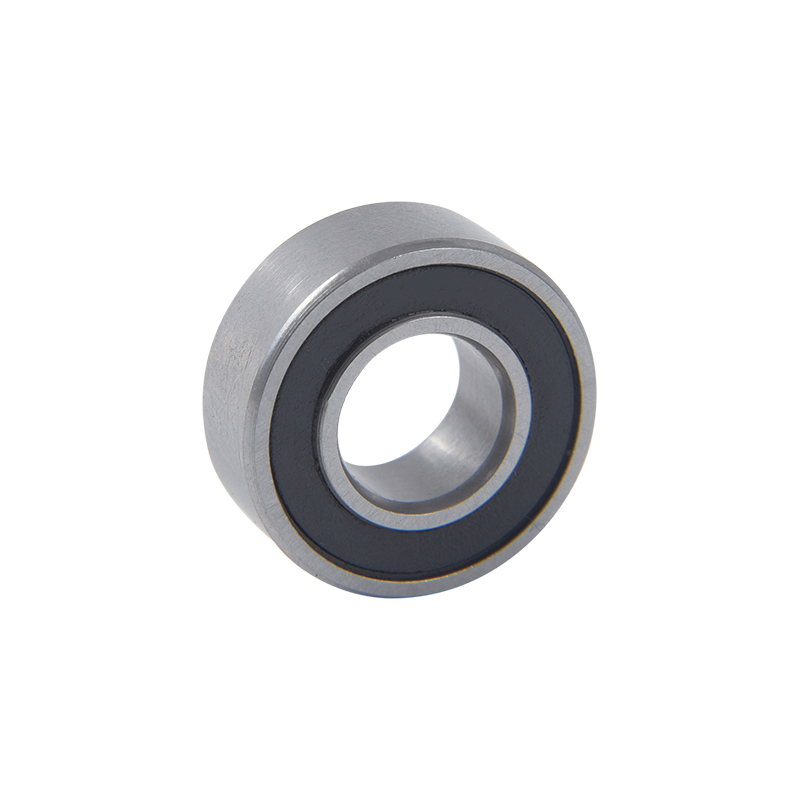

Sealing Options: To protect the internal components from contaminants and retain lubrication, micro precise deep groove ball bearings are available with various sealing options. These may include rubber seals, metal shields, or non-contact seals, depending on the level of protection required.

Cage Design: The cage, or retainer, in micro precise deep groove ball bearings plays a crucial role in maintaining the spacing and alignment of the rolling elements. Advanced cage designs, such as ball-guided or window-type cages, help minimize friction and ensure consistent performance under varying operating conditions.

Customization Options: Manufacturers often offer customization options for micro precise deep groove ball bearings to meet specific application requirements. This may include variations in internal clearance, lubrication, sealing arrangements, and surface coatings tailored to enhance performance in challenging environments.

- [email protected]

- +86-15706849036

- Home

- About Us

- Products

- Flanged Ball Bearing Series

- In Inch Flanged Ball Bearing Series

- 6000 Series Deep Groove Ball Bearing

- 6200 Series Deep Groove Ball Bearing

- 6300 Series Deep Groove Ball Bearing

- 6700 Series Deep Groove Ball Bearing

- 6800 Series Deep Groove Ball Bearing

- 6900 Series Deep Groove Ball Bearing

- 1600 Series Deep Groove Ball Bearing

- 16000 Series Deep Groove Ball Bearing

- Unstandard Series

- MR Series

- In Inch R Series

- In Inch RLS Series、RMS Series

- In Inch EE Series

- Micro Precise Deep Groove Ball Bearing Series

- News Center

- Contact Us

-

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856