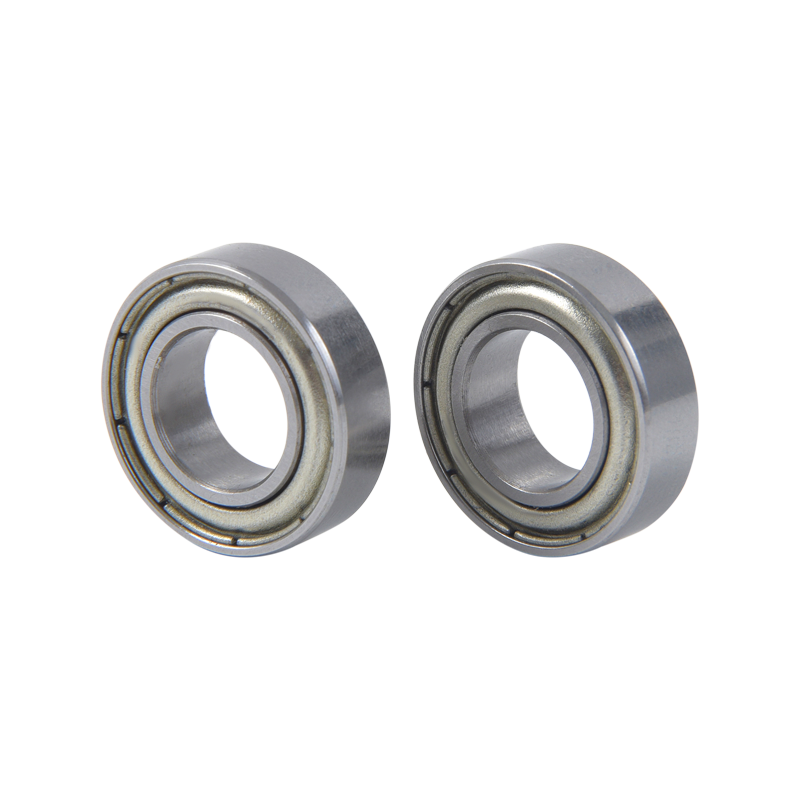

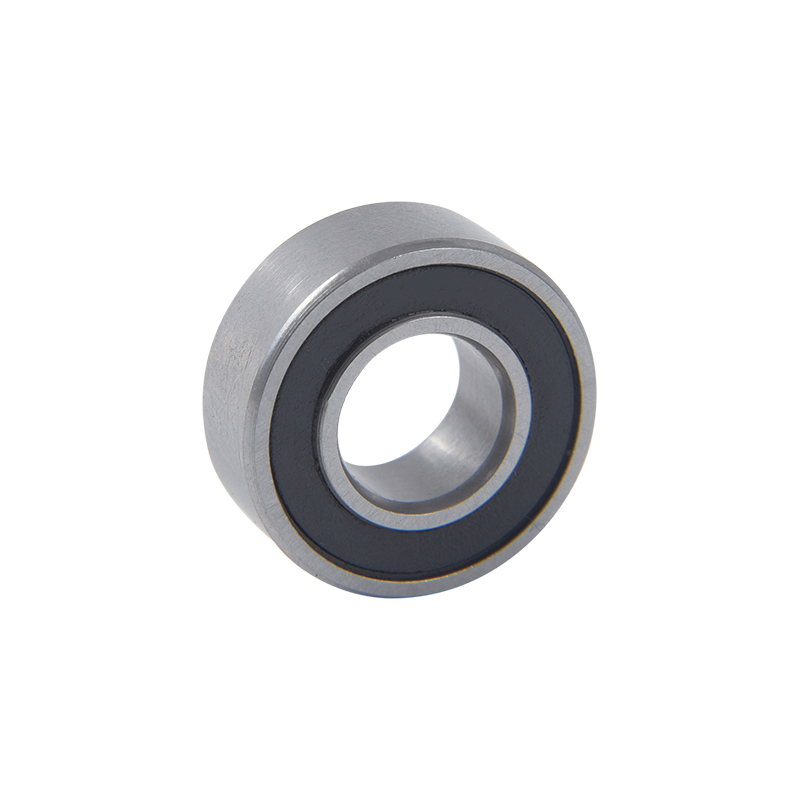

As an important part of the manufacturing industry, textile machinery faces diverse and complex working conditions during its operation. In this context, deep groove ball bearings are one of the key mechanical components, and their load-bearing capacity plays a vital role in mechanical performance and operational stability. This article will focus on the role of load requirements on deep groove ball bearings for textile machinery and how to better meet this requirement during the selection process.

1. Diversity of load requirements:

Textile machinery is subjected to loads from different directions and sizes during the production process. These loads may be radial loads, axial loads or a combination of simultaneous loads. As a key component to bear these loads, deep groove ball bearings must be selected with full consideration of this diversity. Load requirements may vary under different working conditions, so selecting appropriate bearings can better adapt to the actual working environment of the machinery.

2. Load requirements affecting mechanical stability:

Mechanical stability is directly affected by load. If the load-bearing capacity of the deep groove ball bearing is insufficient to meet the actual working load requirements, it may cause vibration, noise or more serious failure of the machine during operation. Therefore, when selecting a model, it is necessary to fully understand the various loads that the machine will bear during operation to ensure that the selected deep groove ball bearing can ensure the smooth operation of the machine.

3. Effect of load on bearing life:

Load directly affects the life of deep groove ball bearings. If a bearing is subjected to a load that exceeds its design load-bearing capacity during long-term operation, the service life of the bearing will be shortened. Therefore, during the selection process, it is necessary to accurately evaluate the actual working load of the machinery and select appropriate bearings to ensure its life and reliability.

4. Design to prevent overload:

In some special circumstances, machinery may face instantaneous or short-term overload conditions. In order to improve the overload resistance of machinery, the selection of deep groove ball bearings needs to take into account the design to prevent overload. This includes additional strength reserves in the bearings and appropriate safety factors to cope with unforeseen load shocks.

5. Adapt to dynamic load changes:

The working load of textile machinery usually changes dynamically, so deep groove ball bearings need to have good dynamic load adaptability. When selecting, attention should be paid to the dynamic load capacity of the bearing to ensure that it can effectively adapt to load fluctuations under working conditions.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856