In the field of precision instrument design and manufacturing, deep groove ball bearings, as key components, have a significant and critical impact on precision and accuracy. This impact occurs at multiple levels, from the characteristics of the bearing itself to its role in the instrument system, and has a profound impact on the performance and accuracy of the final product.

First of all, the accuracy grade of deep groove ball bearings determines the positioning and movement precision of the instrument to a large extent. Precision refers to the repeatability and consistency of measurement results, while accuracy focuses on how close the measurement results are to the actual value. High-precision grade deep groove ball bearings can provide more reliable position control, ensuring that the instrument can achieve the expected performance level during operation.

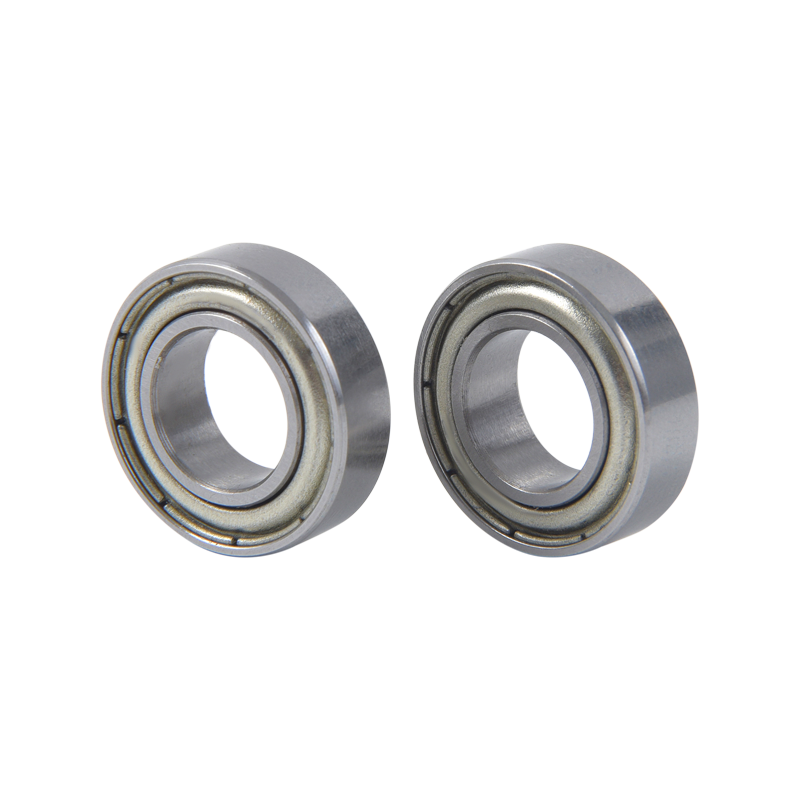

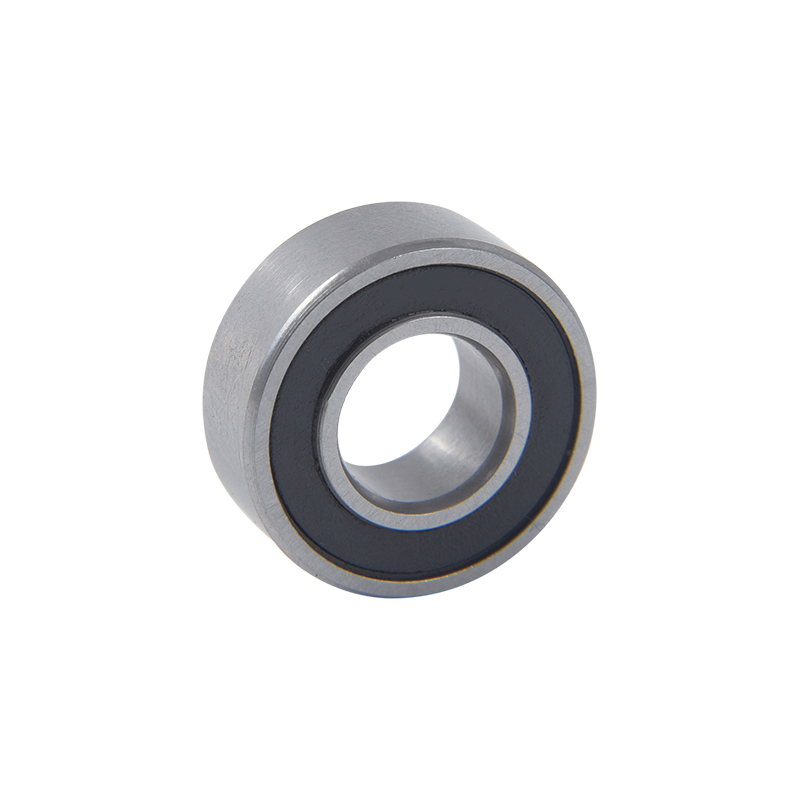

Secondly, deep groove ball bearings play a key role in reducing system friction and improving rotational smoothness. In precision instruments, the requirements for smooth movement of moving parts are particularly stringent to ensure that errors are reduced. Deep groove ball bearings are designed to provide low friction at high rotational speeds, helping to maintain smooth movement of the instrument.

Third, bearing stiffness is an important factor affecting the mechanical stability of precision instruments. High-stiffness deep groove ball bearings help maintain system precision when facing various complex working conditions and environmental challenges. The stability of the system is crucial for applications that require high-precision positioning and measurement, and the stiffness of the bearing is directly related to the system's resistance to external disturbances.

In addition, the assembly and preloading process of deep groove ball bearings are also important links that affect the precision of the instrument. Proper bearing assembly and preloading can reduce clearance and improve instrument precision. During the use of precision instruments, any small amount of play may lead to errors in the system, and proper preloading of deep groove ball bearings can help minimize these potential problems.

Finally, bearing material selection is also critical to its performance in precision instruments. In high-precision instruments, the characteristics of bearing materials are directly related to the stability and wear resistance of the system. Excellent material properties ensure that the bearings will not suffer premature wear or damage during long-term use, thereby maintaining system reliability and accuracy.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856