The impact of fianged bail bearings on noise levels in low-power motors is crucial, and their design and performance directly affect the sound level produced when the motor is running. The following are key aspects that explore the impact of fianged bail bearings on noise levels in low power motors:

1. Control of friction noise:

The design of fianged bail bearings is directly related to the generation of friction noise. By using low friction coefficient materials, surface treatment technology and optimized lubrication solutions, bearing friction noise can be effectively reduced and the motor's running quietness can be improved.

2. Vibration and resonance suppression:

Fianged bail bearings may be subjected to various loads during motor operation, some of which may cause vibration and resonance phenomena. Properly designed fianged bail bearings can reduce vibration and avoid resonance, thereby reducing noise levels.

3. Influence of bearing clearance and looseness:

The design of fianged bail bearings needs to take into account the bearing clearance. Appropriate clearance can reduce bearing vibration and noise. In addition, the installation and fixation of fianged bail bearings also affect their performance. Improper installation may cause the bearings to loosen and increase noise.

4. Material selection and noise characteristics:

Fianged bail bearings of different materials will produce different noise characteristics during operation. Choosing appropriate bearing materials, such as ceramics or low-noise alloys, can effectively reduce motor noise levels.

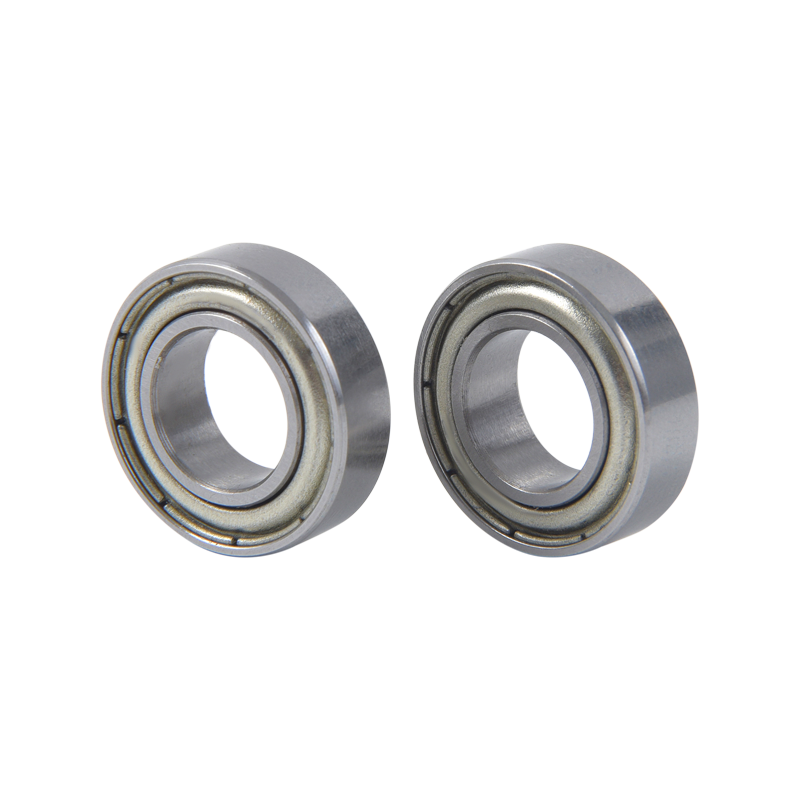

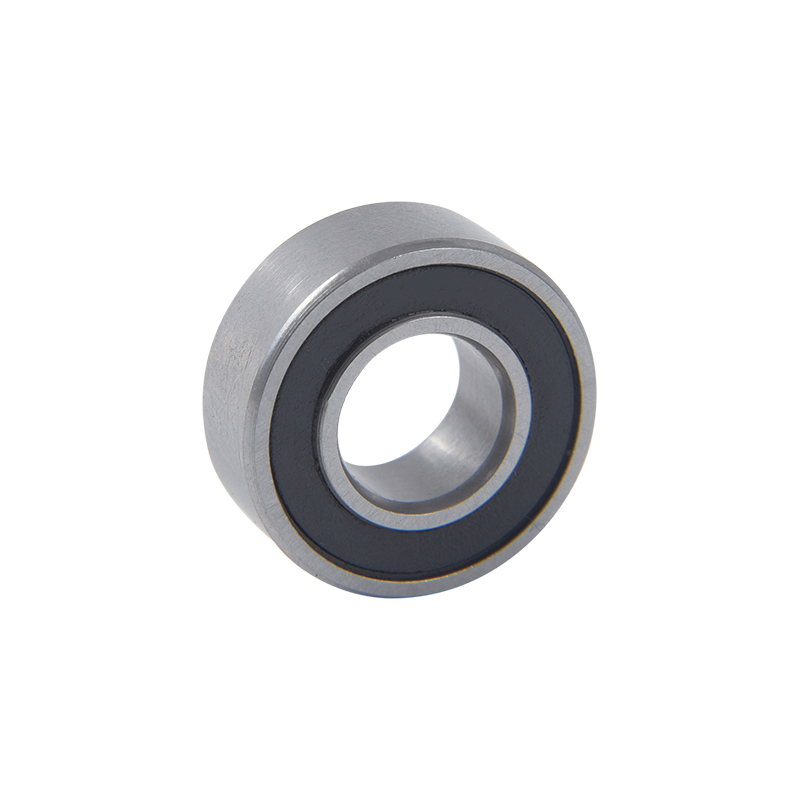

5. Sealing and protection design:

The sealing and protective structure of fianged bail bearings are critical to preventing external contaminants from entering the bearing, reducing friction noise and damping vibration. Excellent sealing design helps reduce noise levels while improving bearing durability.

6. Influence of preload and adjustment:

The preload and adjustment of the fianged bail bearings have a direct impact on the motor noise level. Proper preload can reduce bearing looseness and vibration, helping to reduce noise levels.

7. Relationship between temperature and viscosity:

Fianged bail bearings will generate a certain amount of heat during operation, and heat will affect the viscosity of the lubricating oil. Proper temperature control and lubricant selection can reduce friction and lower noise levels.

8. Influence of manufacturing process:

The manufacturing process of a fianged bearing also directly affects its performance and noise levels. High-precision manufacturing processes help reduce bearing irregularities and improve bearing stability, thereby reducing noise.

9. Control of loss and wear:

Wear and loss of fianged bail bearings is one of the main causes of increased noise. Through reasonable lubrication and lubrication treatment of bearing surfaces, wear and loss can be effectively reduced, and noise levels can be reduced.

10. Long-term running stability:

The long-term operating stability of fianged bail bearings is related to their materials and design. Whether the fianged bail bearing can maintain its performance during long-term operation is directly related to the persistence of noise when the motor is running.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856