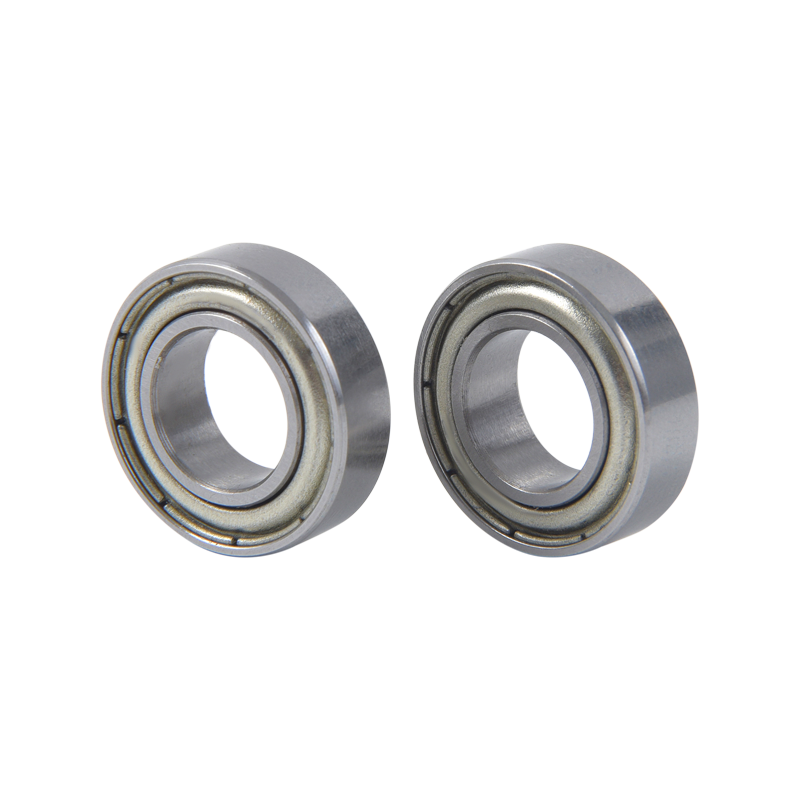

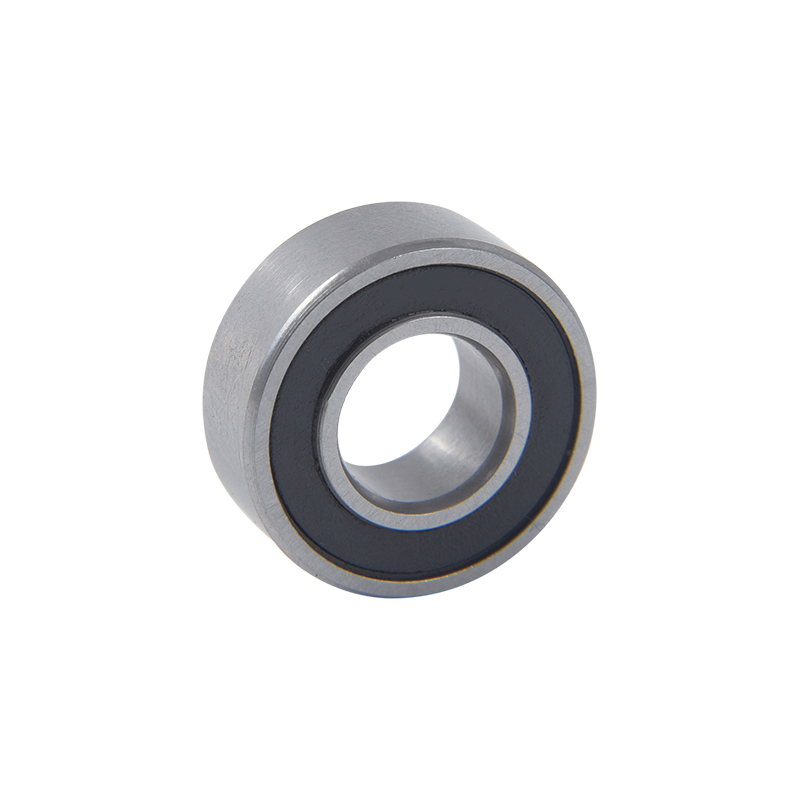

Deep groove ball bearings can indeed play a role in enhancing elevator performance. Elevators rely on various mechanical components, including bearings, to ensure smooth and efficient operation. Deep groove ball bearings offer several advantages that make them suitable for elevator applications.

Load Capacity: Deep groove ball bearings are designed to handle both radial and axial loads. They have a high load-carrying capacity, making them suitable for supporting the weight of the elevator car and its occupants.

Low Friction: Friction reduction is crucial in elevator systems to minimize energy consumption and ensure smooth operation. Deep groove ball bearings have low friction characteristics, enabling efficient power transmission and reduced wear on other elevator components.

High Speeds: Elevators often require high-speed operation, especially in tall buildings. Deep groove ball bearings are capable of handling high rotational speeds, ensuring that the elevator can operate smoothly and reliably.

Vibration and Noise Reduction: Smooth and quiet elevator operation is essential for passenger comfort. Deep groove ball bearings are designed to minimize vibration and noise, providing a quieter and more pleasant ride.

Durability and Reliability: Elevator systems typically undergo frequent and continuous operation, which places significant demands on the mechanical components. Deep groove ball bearings are known for their durability and long service life, making them a reliable choice for elevator applications.

When incorporating deep groove ball bearings into elevator systems, it is essential to consider factors such as bearing size, load ratings, lubrication, and proper installation. Consulting with bearing manufacturers or experts in the field can help ensure the selection of suitable bearings and optimize elevator performance.

It's worth noting that while deep groove ball bearings can contribute to elevator performance, they are just one component of a complex system. Other factors such as motor efficiency, control systems, and maintenance practices also play a vital role in overall elevator performance.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856