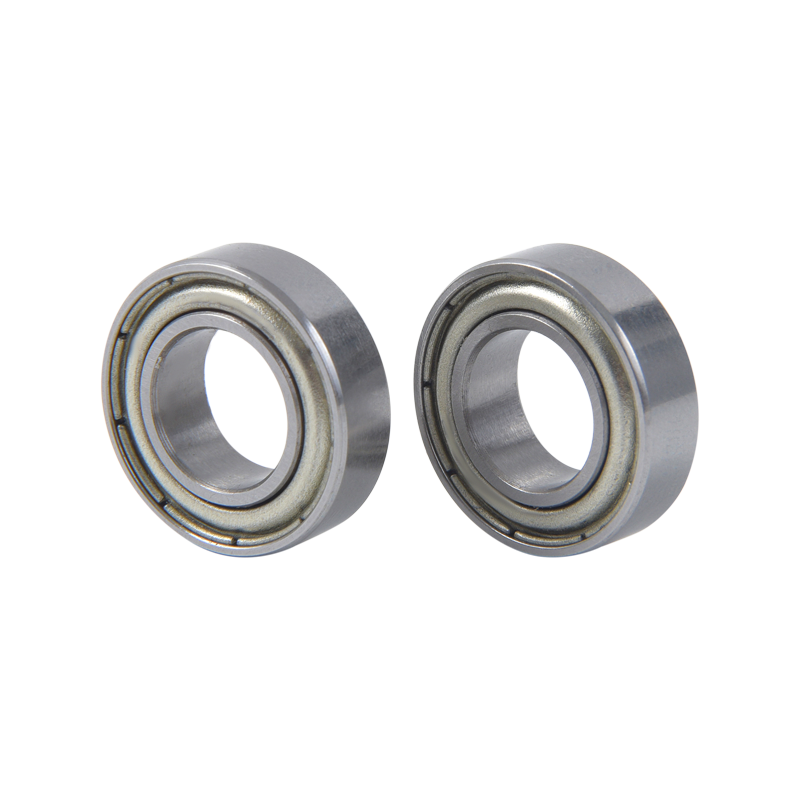

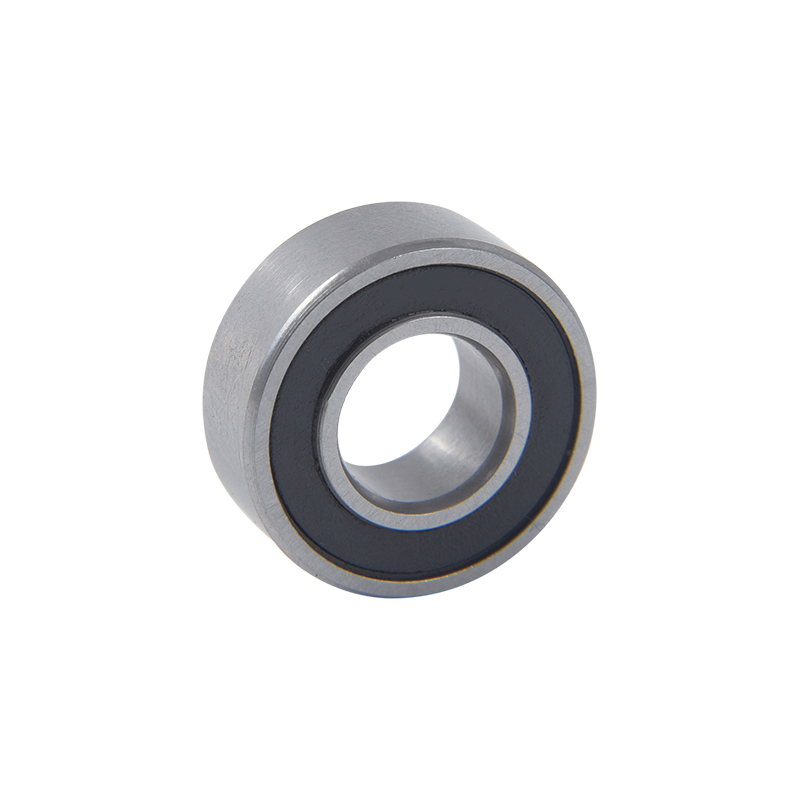

Micro precise deep groove ball bearings are highly specialized components used in various industries that require precision, reliability, and high-speed performance. Here are some applications and industry implications of micro precise deep groove ball bearings:

Aerospace and Defense: Micro precise deep groove ball bearings are vital in aerospace and defense applications, such as aircraft navigation systems, radar systems, and missile guidance systems. These bearings provide precise rotational movement and stable performance in extreme conditions, ensuring the accuracy and reliability of critical components.

Medical Equipment: Micro precise deep groove ball bearings are used in medical equipment, including surgical tools, imaging devices, and laboratory equipment. These bearings enable smooth and precise motion, facilitating accurate diagnosis, treatment, and research processes.

Robotics and Automation: Micro precise deep groove ball bearings play a crucial role in robotics and automation applications, such as industrial robots, robotic arms, and automated assembly lines. They provide precise and smooth movement, allowing robots to perform intricate tasks with accuracy and repeatability.

Semiconductor Manufacturing: In the semiconductor industry, micro precise deep groove ball bearings are used in wafer handling and inspection equipment. These bearings ensure precise positioning and alignment of delicate wafers during the manufacturing process, minimizing defects and optimizing production yields.

Precision Machinery: Various precision machinery applications rely on micro precise deep groove ball bearings, such as high-speed spindles in machine tools, optical devices, and printing presses. These bearings enable smooth and stable rotation at high speeds, resulting in superior performance and product quality.

Automotive Industry: Micro precise deep groove ball bearings are used in automotive applications, particularly in advanced braking systems, transmission systems, and electric powertrains. These bearings provide low friction, high durability, and precise operation, contributing to improved vehicle performance, efficiency, and safety.

Mechatronics and Electronics: Micro precise deep groove ball bearings are found in mechatronic systems and electronic devices, such as hard disk drives, precision motors, and consumer electronics. They offer reliable and precise rotational motion, ensuring the proper functioning of these devices.

The industry implications of micro precise deep groove ball bearings include enhanced product performance, increased manufacturing efficiency, improved accuracy, reduced downtime, and higher productivity. These bearings enable the development of advanced technologies and applications, driving innovation in multiple sectors. Moreover, their reliability and precision contribute to overall system reliability, ensuring the safety and effectiveness of various industrial processes and equipment.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856