Improving efficiency in machinery is always a priority, and one way to achieve this is by utilizing non-standard bearings. While standard bearings are commonly used in various applications, non-standard bearings offer unique advantages that can greatly enhance performance.

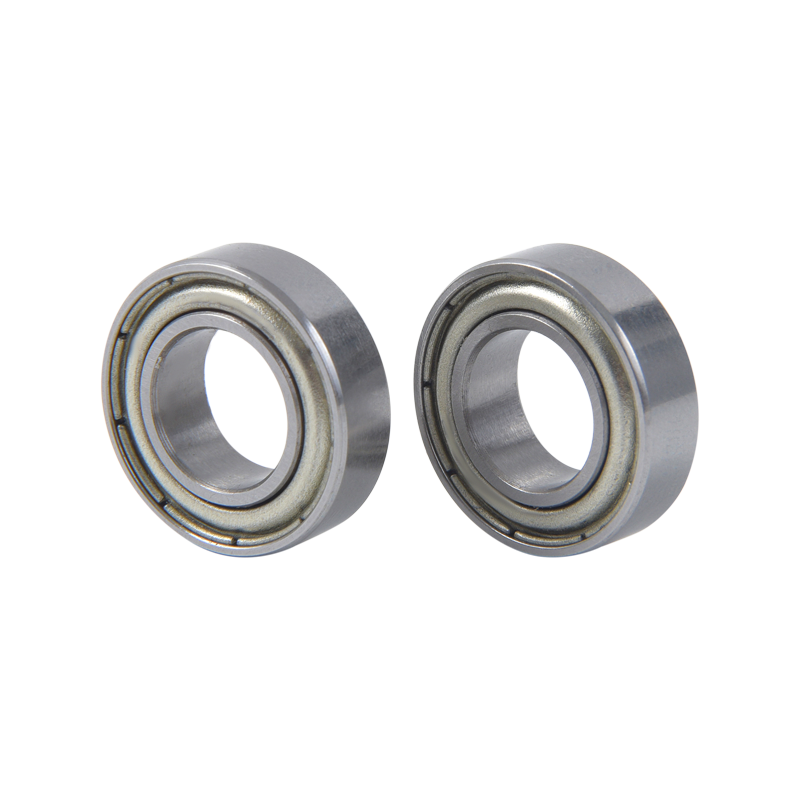

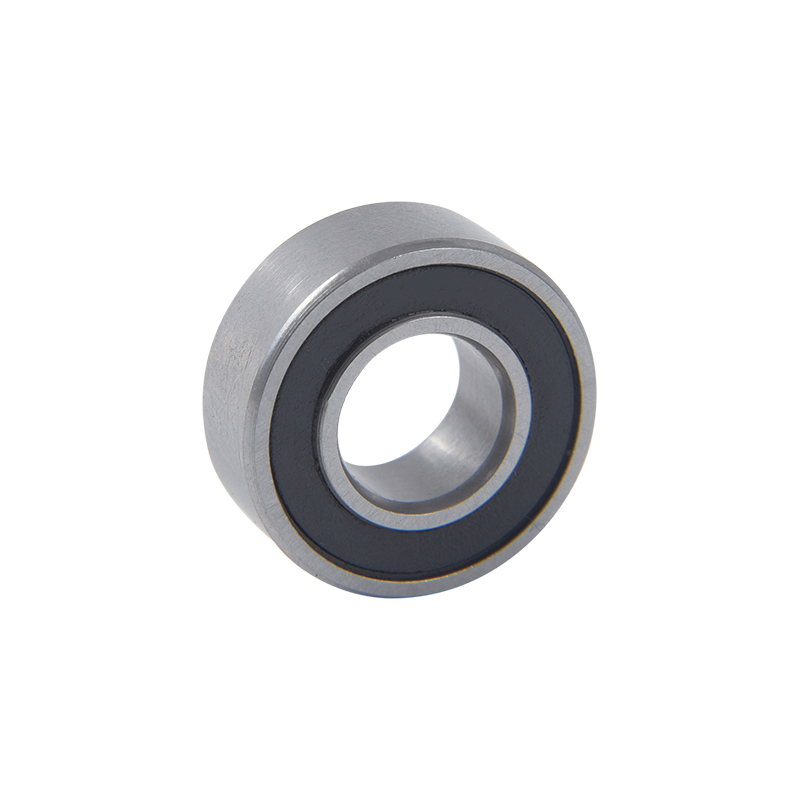

Non-standard bearings, also known as custom bearings or specialty bearings, are specifically designed to meet the unique requirements of a particular machinery or equipment. Unlike standard bearings, which are mass-produced and have standardized dimensions, non-standard bearings are customized to fit specific applications.

One of the primary ways non-standard bearings improve efficiency is through their optimized design. These bearings are engineered to reduce friction and minimize energy losses, resulting in improved overall machinery efficiency. By reducing friction, non-standard bearings offer smoother operation, which in turn reduces wear and tear on the machinery and extends its lifespan. Additionally, reduced friction leads to lower energy consumption, making the machinery more energy-efficient.

Another advantage of non-standard bearings is their ability to handle higher loads and work in challenging operating conditions. These custom bearings can be designed with different materials, coatings, or surface treatments to enhance their performance in specific environments. For example, non-standard bearings can be made to withstand high temperatures, extreme pressures, corrosive substances, or even operate in underwater conditions. By withstanding these harsh conditions, non-standard bearings improve machinery performance and reliability.

Furthermore, non-standard bearings provide flexibility in machinery design and construction. With custom bearings, engineers have more freedom to innovate and optimize the design of their machinery. By tailoring the bearings to the specific requirements of the application, engineers can achieve better alignment, reduce weight, improve balance, and optimize the entire system for maximum efficiency.

It is worth mentioning that non-standard bearings are not limited to their applications in large industrial machinery. They can also be utilized in smaller devices, such as medical equipment, robotics, or precision instruments. In these cases, the superior performance and efficiency provided by non-standard bearings are crucial for achieving accurate and reliable operations.

In conclusion, non-standard bearings play a significant role in enhancing the performance and efficiency of machinery. By offering optimized design, the ability to handle challenging conditions, and flexibility in machinery construction, non-standard bearings optimize energy usage, extend machinery lifespan, and improve overall performance. Therefore, considering non-standard bearings for specific applications can result in substantial efficiency improvements in various industries.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856