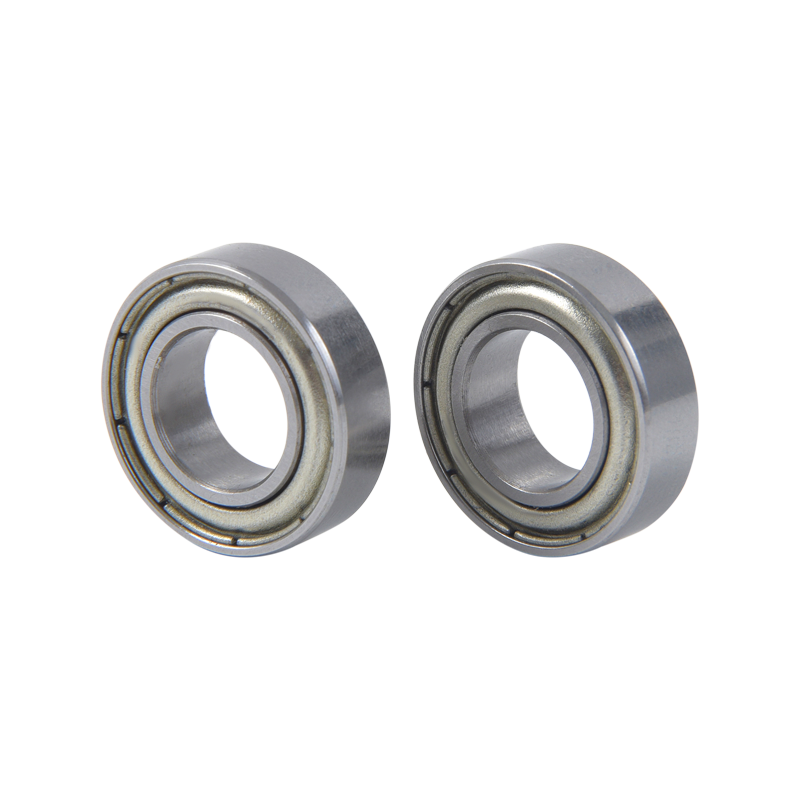

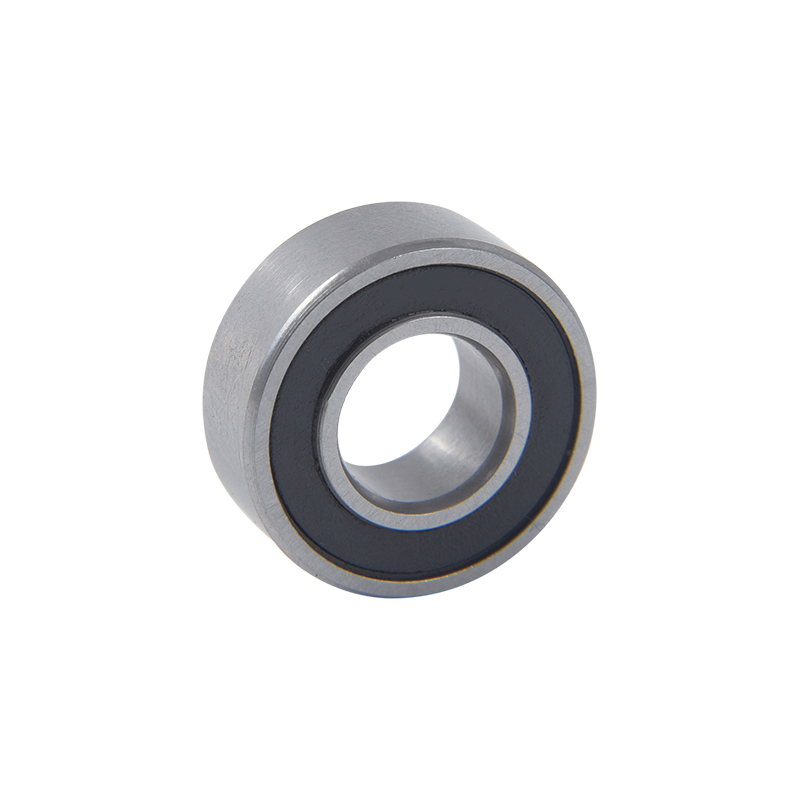

As industrial technology rapidly advances, bearings, as crucial components of mechanical systems, continue to evolve to meet the demands of different application areas in modern industry. The innovation of non-standard bearings has become a key way to address these evolving needs. Non-standard bearings are customized or specially designed to meet specific requirements that traditional bearings may struggle to fulfill. Let's delve into the significance of non-standard bearing innovation in modern industry:

Adaptation to Diverse Needs: Modern industry requires bearings to adapt to increasingly diverse needs. The innovation of non-standard bearings enables them to meet these diverse requirements, including high-temperature, low-temperature, high-speed, high-load, and special environmental conditions.

Enhanced Performance: Custom-designed non-standard bearings are instrumental in improving performance. They can increase load-carrying capacity, reduce friction, and extend the service life, thereby enhancing the efficiency of industrial equipment and reducing downtime and maintenance costs.

Reduced Energy Consumption: Innovative non-standard bearing designs can help reduce energy consumption. For instance, bearings used in renewable energy equipment, such as wind turbines, can minimize mechanical losses, boost system efficiency, and contribute to sustainable energy development.

Expanded Application Areas: The innovation of non-standard bearings has spurred the expansion of bearing application areas. These bearings can cater to a wide array of industries, including aerospace, medical devices, food processing, robotics, and more, facilitating technological advancements in these fields.

Lower Maintenance Costs: Some non-standard bearings incorporate self-lubricating technology or possess long-life characteristics, reducing maintenance requirements and associated costs. This is critical for equipment reliability and maintainability.

Innovative Materials: Innovation in non-standard bearings encompasses the use of novel materials like ceramics, polymers, and composites. These materials offer improved performance, reduced friction, and extended service life.

Digital Technology: Certain non-standard bearings integrate digital sensors and monitoring technology, enabling real-time operating status monitoring, advanced fault detection, predictive maintenance, and enhanced equipment reliability.

In summary, non-standard bearing innovation is of paramount importance in addressing the evolving needs of modern industry. These bearings provide flexible solutions for changing application areas and challenges, allowing industrial equipment to meet escalating performance, efficiency, and sustainability requirements. The ongoing innovation of non-standard bearings will continue to drive technological progress and innovation in the industrial sector. Thus, these non-standard bearings are not just essential for modern industry, but also leaders in shaping the future of industry.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856