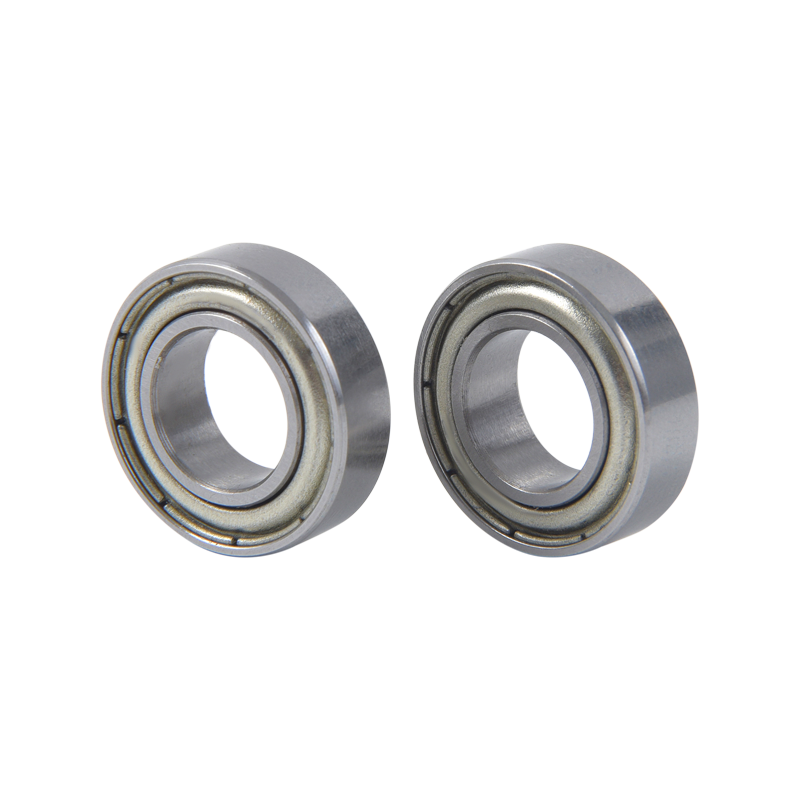

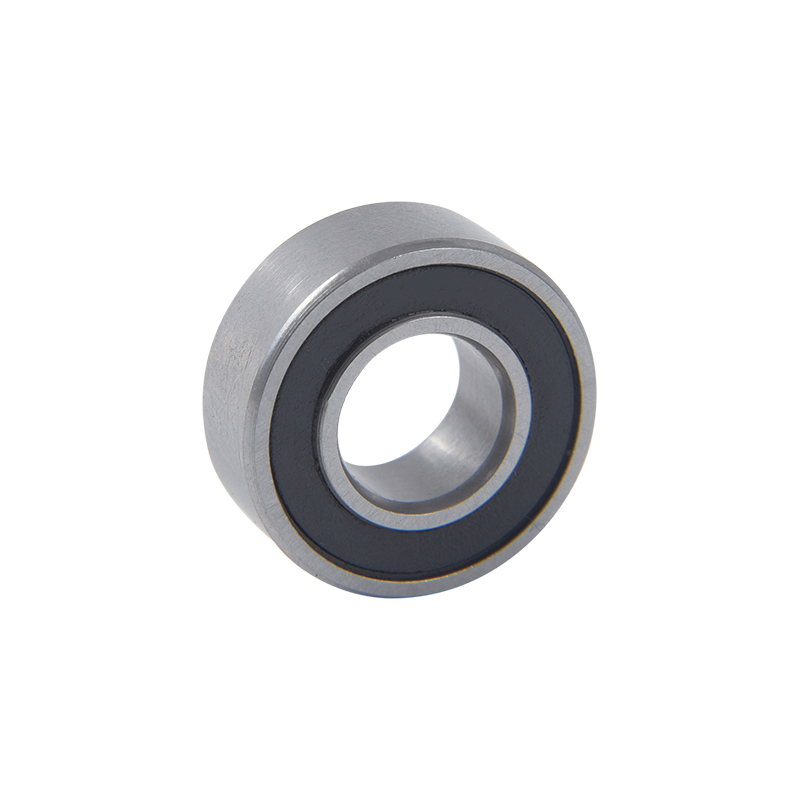

Unstandard series deep groove ball bearings for small power motors offer several unique features that distinguish them from standard bearings. These features are designed to optimize performance and reliability in specific applications. Here are the key characteristics of unstandard series deep groove ball bearings:

Non-standard Dimensions: Unstandard series bearings are customized to meet specific dimensional requirements that deviate from industry-standard sizes. This flexibility allows for a more precise fit within the motor assembly, optimizing performance and minimizing space constraints.

Specialized Load Capacity: These bearings are engineered to handle the specific load requirements of small power motors. They are designed to provide reliable operation and durability under the anticipated loads and operating conditions of the motor.

Enhanced Efficiency: Unstandard series bearings often incorporate design modifications to reduce friction and increase overall efficiency. This can result in improved motor performance, reduced energy consumption, and extended bearing life.

Customized Sealing Options: Unstandard bearings can be equipped with specialized sealing arrangements to protect against contamination and extend bearing life in harsh or challenging environments. This customization ensures optimal protection for the motor and enhances its reliability.

Application-Specific Materials: Depending on the operating conditions and environmental factors, unstandard series bearings can be manufactured using materials that are best suited for the application. This may include corrosion-resistant coatings or high-temperature-resistant materials to ensure longevity and performance.

Precision Manufacturing: These bearings undergo rigorous manufacturing processes to maintain high levels of precision and quality control. This attention to detail ensures consistent performance and reliable operation in small power motor applications.

It is worth noting that unstandard series deep groove ball bearings are typically produced on a made-to-order basis, tailored to the specific requirements of the motor application. This customization allows for optimal performance and efficiency in various operating conditions, making them a suitable choice for small power motors.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856