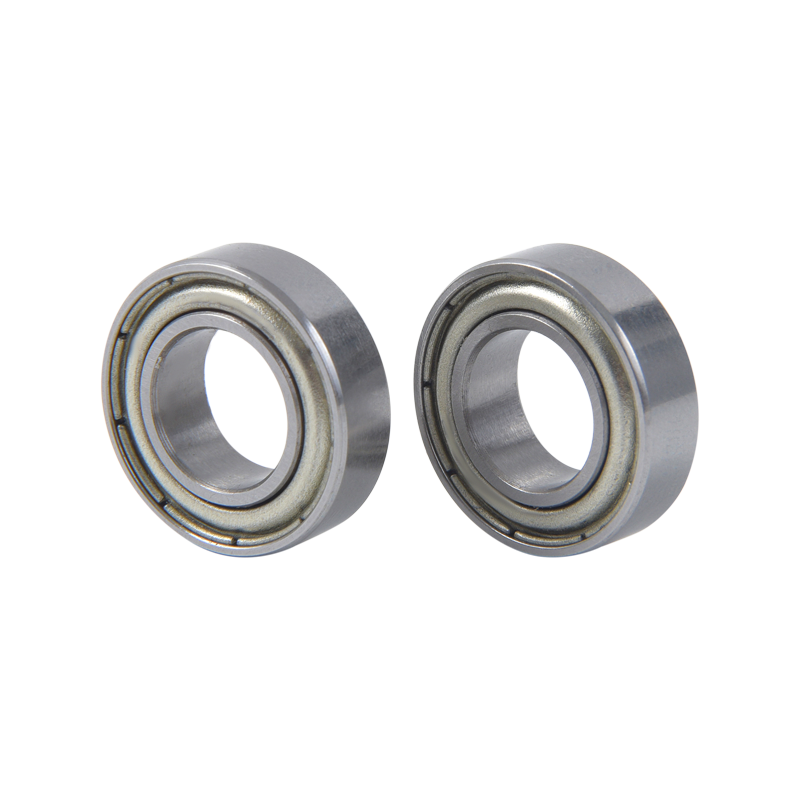

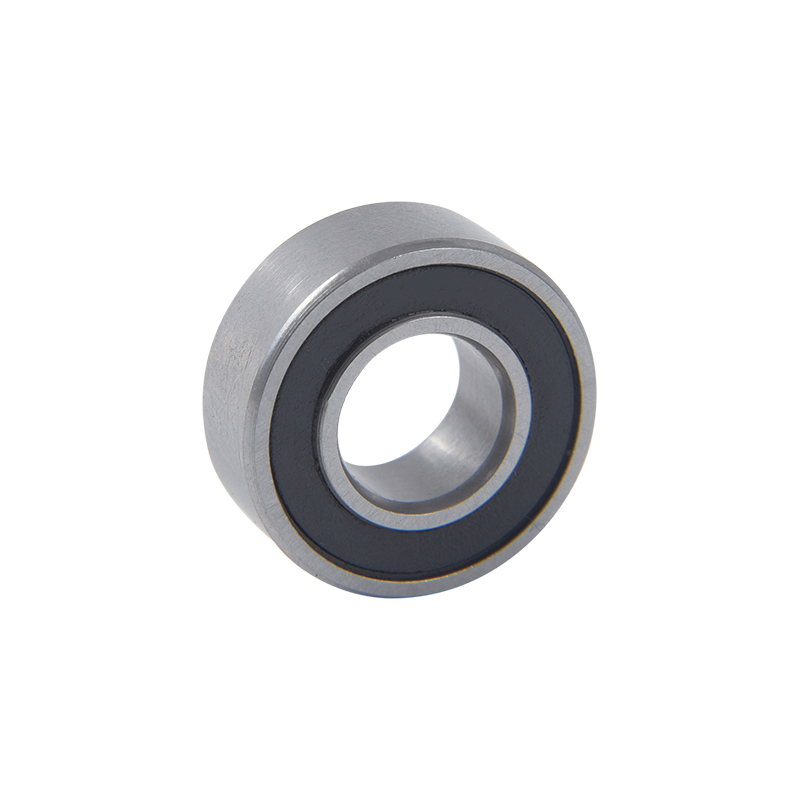

Inch flanged ball bearings are indeed a versatile solution for precision machinery. These bearings are designed to provide accurate and smooth rotational motion in various industrial applications. The flanged design adds an additional feature that allows for easier mounting and positioning of the bearing.

Here are some key features and benefits of inch flanged ball bearings:

Precision and Accuracy: Inch flanged ball bearings are manufactured to tight tolerances, ensuring precise and accurate rotational motion. This makes them ideal for applications that require high levels of precision, such as machine tools, robotics, and medical equipment.

Versatility: These bearings can accommodate radial and axial loads simultaneously, making them suitable for a wide range of applications. They can handle both light and moderate loads, making them versatile in different operating conditions.

Flanged Design: The flange on the outer ring of the bearing serves multiple purposes. It provides a surface for easy mounting and positioning of the bearing, eliminating the need for separate mounting brackets or housings. The flange also helps in axial location, providing better stability and preventing axial movement of the bearing.

Space Saving: The flange design allows for compact installations, saving space in machinery and equipment. The flange eliminates the need for additional components or structures to support or hold the bearing, making it a space-efficient solution.

Easy Maintenance: Inch flanged ball bearings are typically designed for easy maintenance. They can be easily disassembled and reassembled, allowing for convenient inspection, cleaning, and lubrication. This feature simplifies maintenance procedures and reduces downtime in industrial operations.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856