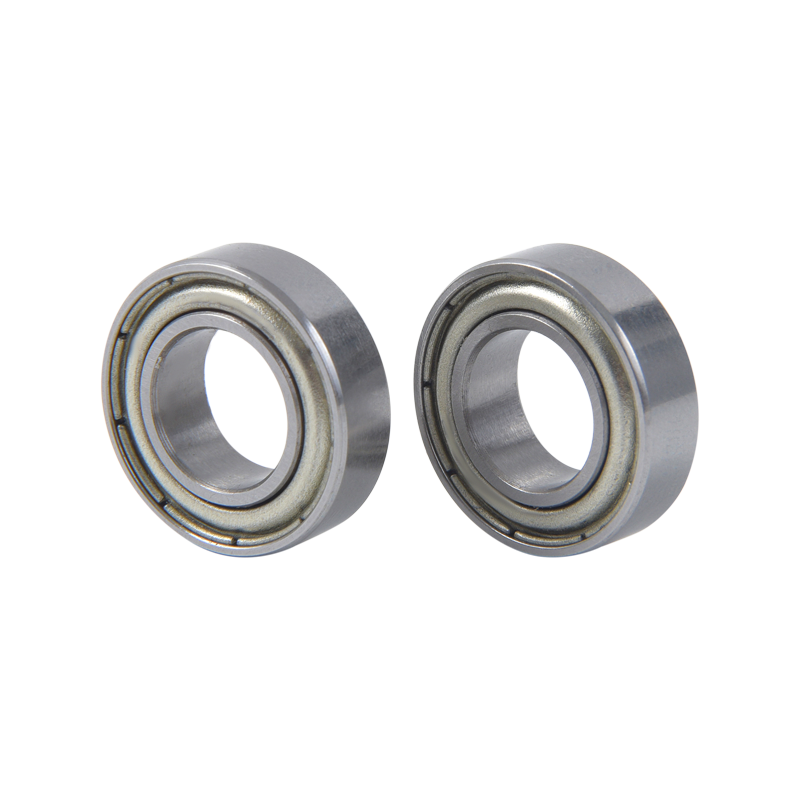

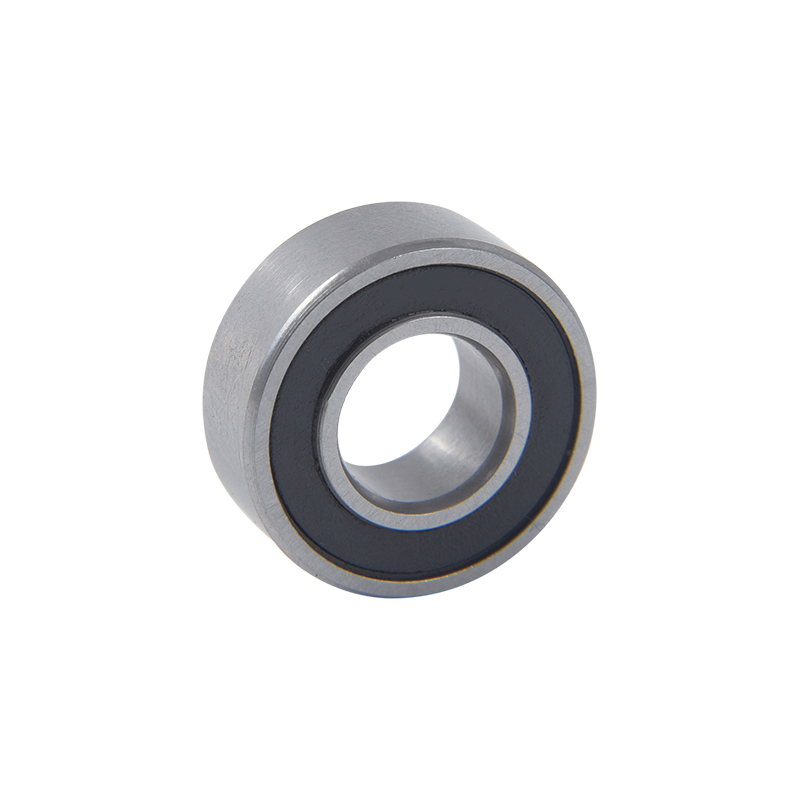

Non-standard bearings, also known as tailor-made precision bearings, are specialized bearings that are designed and manufactured to meet unique or specific application requirements. While standard bearings are widely available and commonly used in various industries, non-standard bearings are crafted to address specific challenges or achieve specific performance goals.

Custom Design: Non-standard bearings are designed to meet specific application requirements that cannot be fulfilled by off-the-shelf standard bearings. This involves tailoring various parameters such as dimensions, load capacities, operating speeds, temperature ranges, and environmental conditions to ensure optimal performance.

Specialized Applications: Non-standard bearings find applications in a wide range of industries and sectors. They are commonly used in industries such as aerospace, automotive, robotics, medical equipment, marine, defense, and high-precision machinery. These bearings are employed in critical systems where standard bearings may not provide the necessary level of precision, durability, or reliability.

Performance Optimization: Non-standard bearings are engineered to optimize performance in unique operating conditions. This may involve modifications to bearing materials, lubrication systems, sealing mechanisms, or even the addition of specialized features like ceramic balls, coatings, or cages. These enhancements can improve factors such as load capacity, speed capability, noise reduction, vibration resistance, and corrosion resistance.

Precision Manufacturing: Tailor-made precision bearings are typically produced using advanced manufacturing processes and technologies. Techniques like computer numerical control (CNC) machining, grinding, superfinishing, and precision assembly are employed to ensure the highest level of accuracy, tight tolerances, and consistent quality.

Cost Considerations: Non-standard bearings are generally more expensive compared to standard bearings due to their custom design, specialized manufacturing processes, and lower production volumes. However, the cost is often justified by the enhanced performance, extended lifespan, reduced downtime, and improved overall system efficiency that these bearings provide.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856