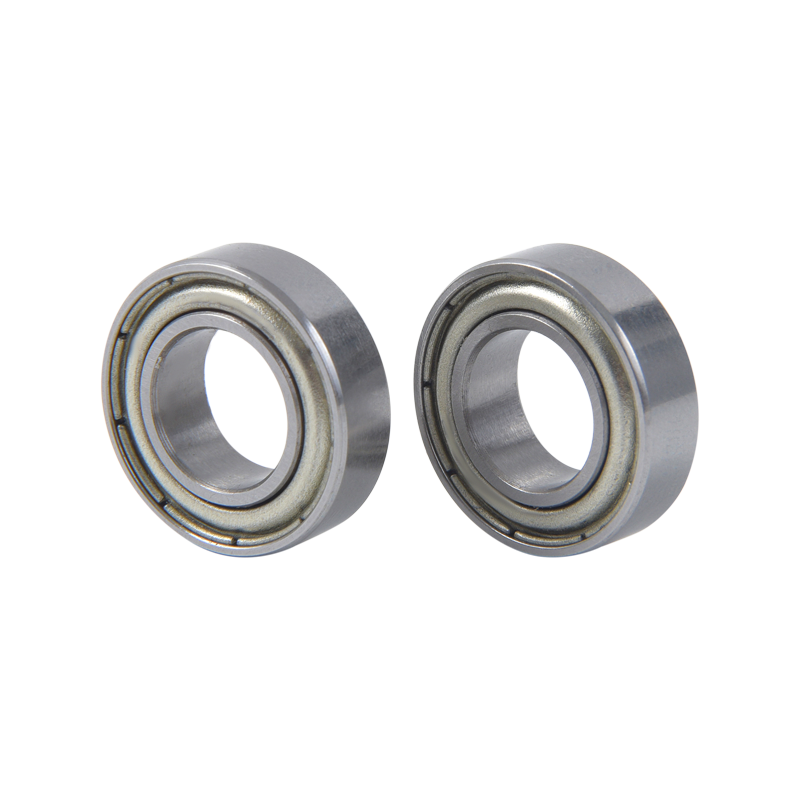

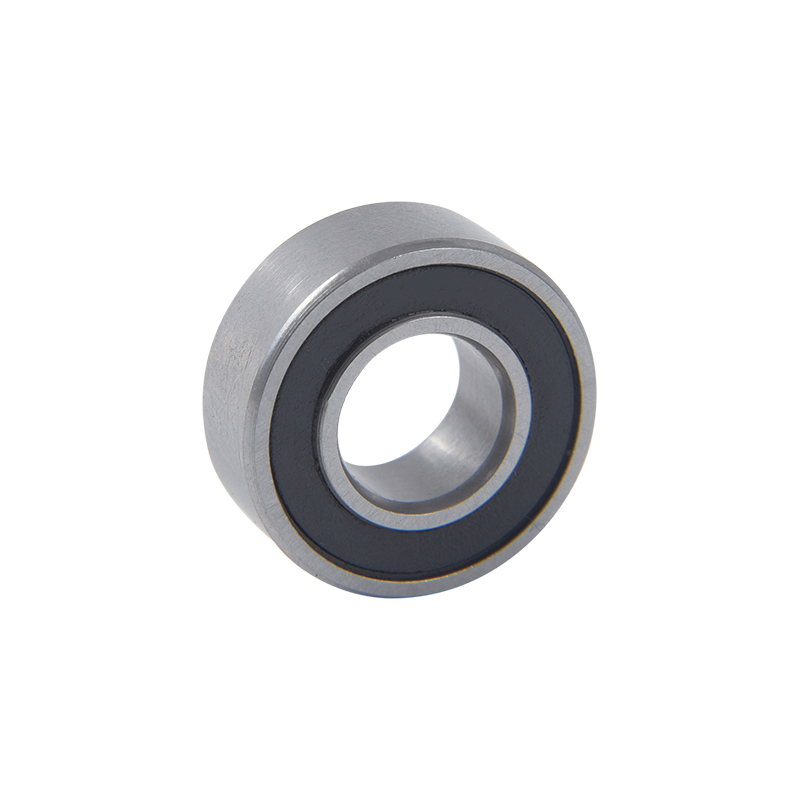

Flanged ball bearings are a type of bearing that has a flange attached to one end of the outer ring. This flange provides several advantages over standard ball bearings, including improved axial support, increased stability, and simplified mounting. Here is a comprehensive overview of the advantages of flanged ball bearings:

Improved axial support: Flanged ball bearings provide improved axial support compared to standard ball bearings because the flange acts as a retaining ring that prevents the bearing from moving in one direction. This is especially important in applications where there is a lot of axial load, such as in conveyor systems, because it helps prevent the bearing from being pushed out of position.

Increased stability: The flange on a flanged ball bearing also provides increased stability compared to a standard ball bearing. The flange acts as a brace against lateral movement, which can help prevent the bearing from twisting or turning during operation. This is particularly useful in applications where the bearing is exposed to high vibration or shock loads.

Simplified mounting: Flanged ball bearings are easier to mount than standard ball bearings because the flange provides a convenient surface for attaching the bearing to a housing or shaft. This can save time and effort during installation, and it also ensures that the bearing is properly aligned.

Reduced cost: Flanged ball bearings can be more cost-effective than standard ball bearings in certain applications because they eliminate the need for separate retaining rings or other components. This can result in a lower overall cost of ownership for the equipment.

Improved sealing: Some flanged ball bearings come with integrated seals or shields that provide better protection against contamination and moisture than standard ball bearings. This can help extend the life of the bearing and reduce maintenance costs.

In conclusion, flanged ball bearings offer several advantages over standard ball bearings, including improved axial support, increased stability, simplified mounting, reduced cost, and improved sealing. These advantages make them a popular choice for a wide range of industrial and commercial applications.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856