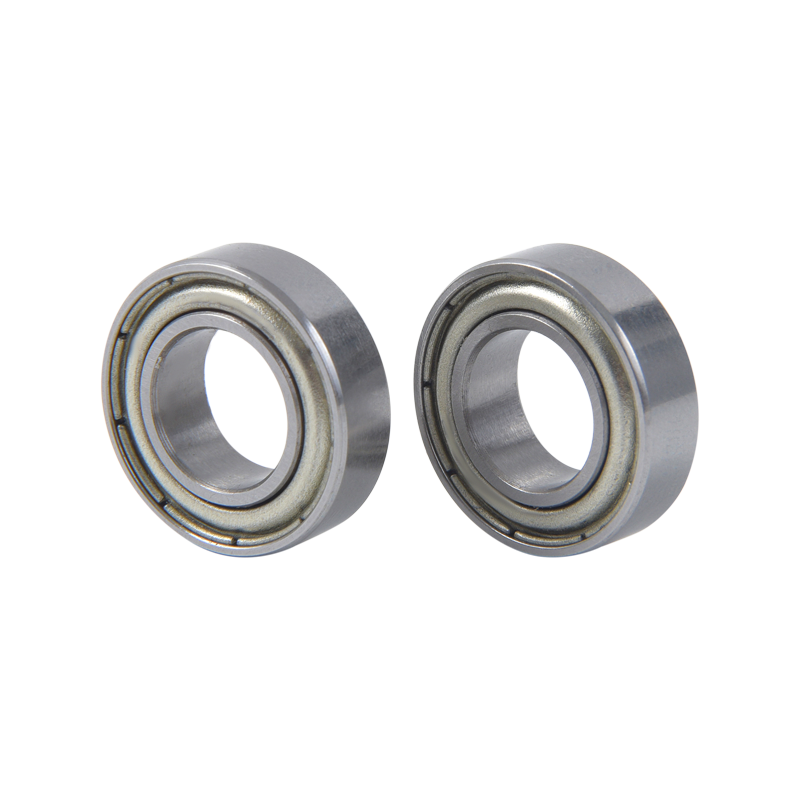

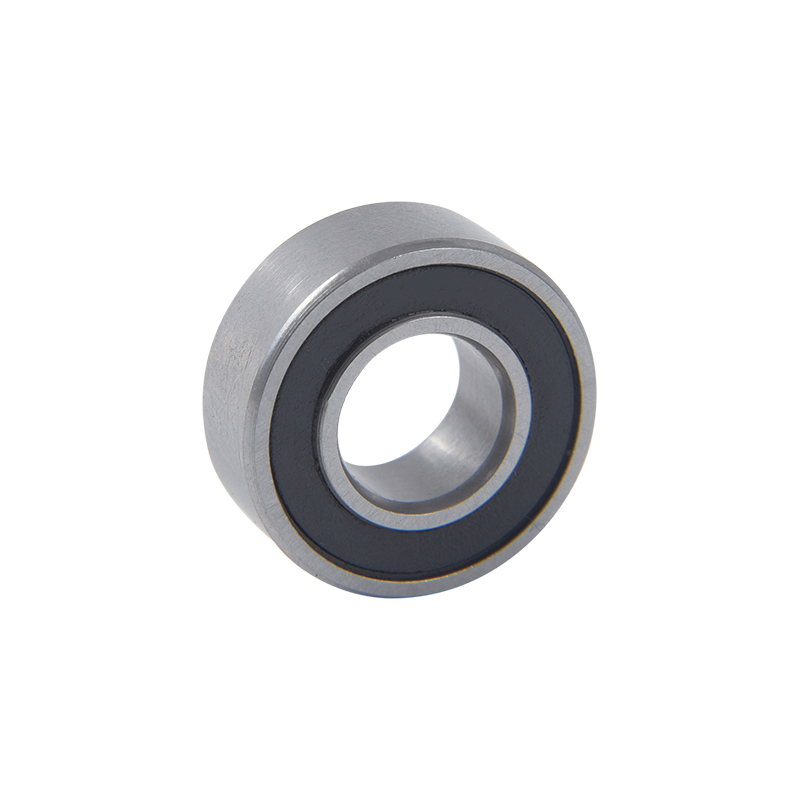

Bearings play a critical role in the efficient operation of many industrial systems. They help reduce friction between moving parts, improve performance, and extend the lifespan of machinery. Non-standard bearings can offer unique advantages over standard bearings, allowing for greater customization and optimization of industrial systems.

Here are some ways non-standard bearings can maximize performance and efficiency in industrial systems:

Customization: Non-standard bearings can be designed to fit specific requirements and constraints of a particular industrial application. Custom bearings can be made to accommodate higher loads, higher speeds, or harsher operating conditions.

Size optimization: Non-standard bearings can be designed to be smaller than standard bearings, reducing the size and weight of the machinery they are used in. Smaller bearings can also reduce the amount of lubricant required, which can improve efficiency and reduce maintenance costs.

Material selection: Non-standard bearings can be made from a wider range of materials than standard bearings, allowing for greater customization to suit specific operating conditions. For example, bearings made from advanced ceramics can provide improved wear resistance, corrosion resistance, and high-temperature performance.

Lubrication optimization: Non-standard bearings can be designed with specific lubrication requirements in mind, reducing friction and improving efficiency. Bearings can be designed with features such as grooves or pockets to hold lubricant and reduce the need for frequent lubrication.

Improved performance: Non-standard bearings can provide improved performance over standard bearings. For example, hybrid bearings that combine ceramic balls with steel races can provide reduced friction and improved resistance to wear, resulting in longer bearing life and improved efficiency.

Overall, non-standard bearings can offer significant benefits in terms of customization, size optimization, material selection, lubrication optimization, and improved performance. By working with a knowledgeable bearing supplier, industrial system designers can take advantage of these benefits to optimize the performance and efficiency of their machinery.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

No. 7, Tangchuang Garden, Yangshan Village, Di Tang Street, Yuyao City, Ningbo City, Zhejiang Province, China.

+86-15706849036

+86-15706849036 +86-0574-63267578

+86-0574-63267578 +86-0574-63265856

+86-0574-63265856